Strip hot melt adhesive production line

The production process of strip hot melt adhesive (Hot Melt Adhesive, HMA) usually includes the following steps, which can be adjusted and optimized according to specific needs.

Sep 13,2023

Sep 13,2023

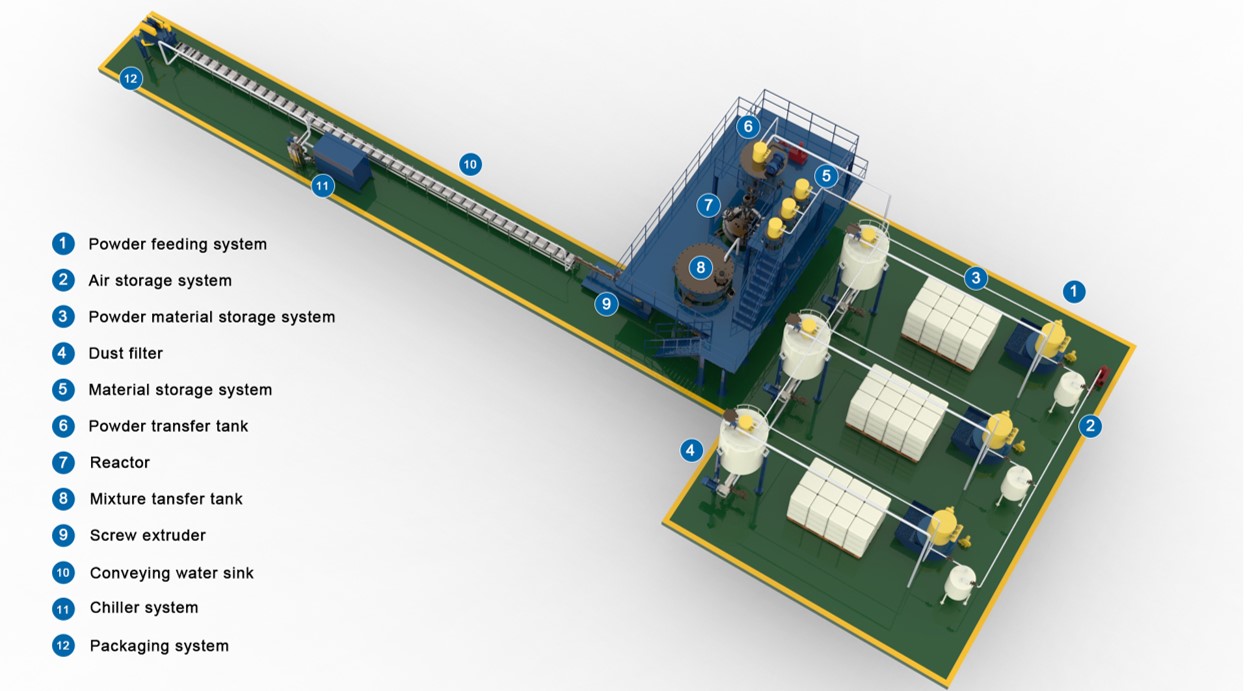

What equipment is needed for the strip hot melt adhesive production line?

Here is a list of the essential equipment typically found in a strip hot melt adhesive production line:

Raw Material Handling Equipment:

Material Silos or Containers: For storing raw hot melt adhesive pellets or granules.

Aug 25,2023

Aug 25,2023

Lithium battery anode material reactor

A reactor used for the production of lithium battery anode materials is a specialized piece of equipment designed for the synthesis and processing of materials used in lithium-ion batteries. Lithium battery anode materials are typically composed of materi

Aug 21,2023

Aug 21,2023

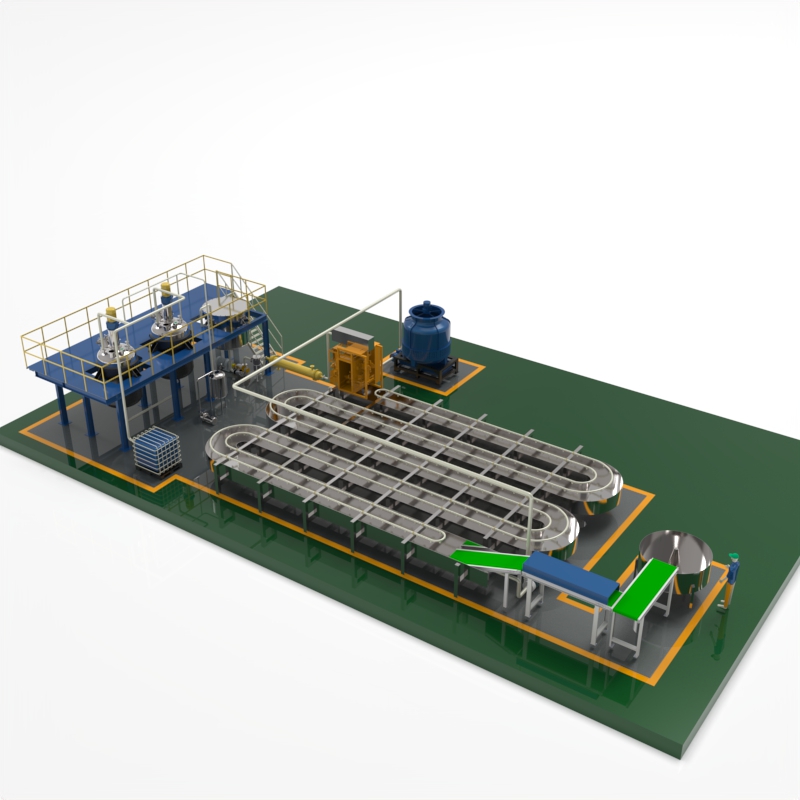

Introduction of Hot Melt Adhesive Production Line

Hot melt adhesive production lines are specialized equipment designed for the continuous manufacturing of hot melt adhesives. Hot melt adhesives are thermoplastic materials that become liquid when heated and solidify when cooled, forming a strong bond wit

Apr 17,2023

Apr 17,2023

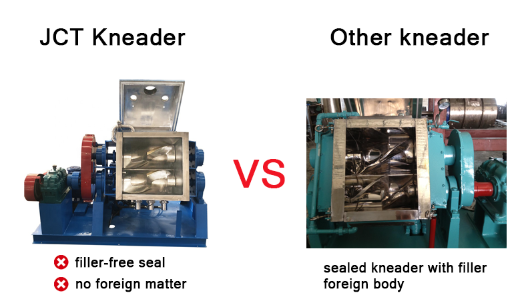

JCT Machinery A filler-free seal kneader

A filler-free seal kneader is a type of kneading machine used in the rubber and plastic industry that is specifically designed for compounding and mixing materials without the use of fillers. Fillers are materials such as carbon black or silica that are a

Apr 12,2023

Apr 12,2023

Application of underwater granulation of hot melt adhesive for pillow core

Underwater granulation involves the formation of granules by forcing a molten material through a die and into a water bath where it solidifies into small particles. In the case of hot melt adhesive for pillow core production, the granules could be formed

Apr 11,2023

Apr 11,2023

Maintenance and maintenance of the reactor

Stainless steel reaction kettles are generally kettle-type reactors with stirring devices,

Oct 18,2022

Oct 18,2022

High Efficiency Hot Melt Glue Stick Production Line——Foshan Jct Machinery Co., Ltd.

1. The hot melt glue stick assembly line should be operated by experienced personnel after training.

Sep 15,2022

Sep 15,2022

Cold knowledge about stainless steel reactor unsaturated resin production line

Regarding the cold knowledge of the reactor unsaturated resin production line, our company Jinchangtai Machinery Equipment Co., Ltd. has the most say.

Sep 15,2022

Sep 15,2022

CN

CN

HOME

HOME

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address