Strip hot melt adhesive production line

Sep 13,2023

Sep 13,2023

JCT

JCT

The production process of strip hot melt adhesive (Hot Melt Adhesive, HMA) usually includes the following steps, which can be adjusted and optimized according to specific needs.

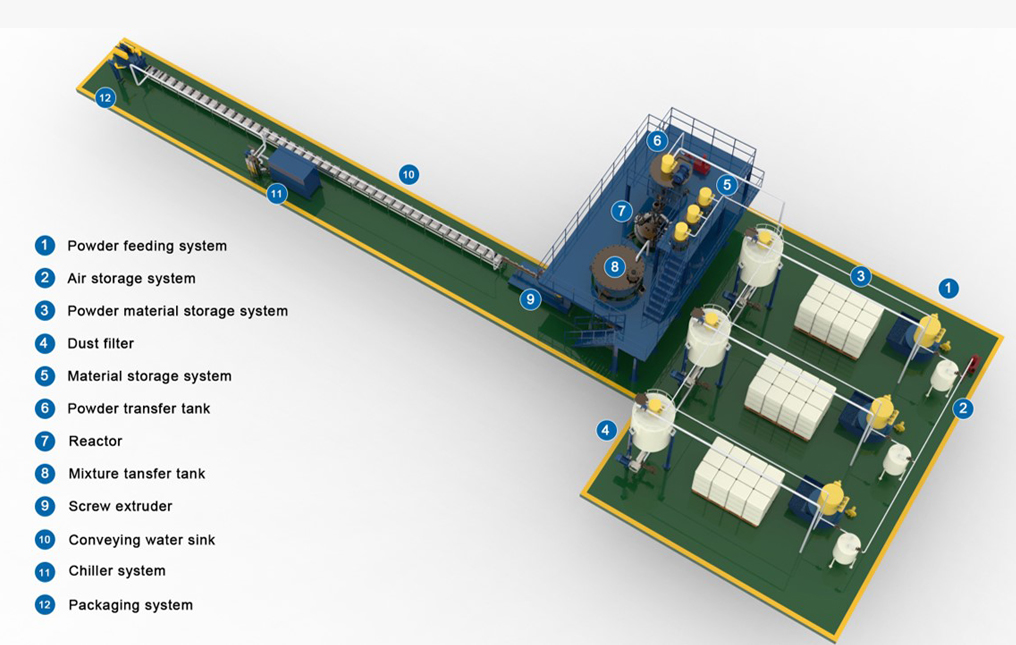

Overview of strip hot melt adhesive production line

Raw material preparation

This is the first step in the production process and requires the preparation of raw materials for hot melt adhesive, which usually include hot melt adhesive resin, additives, fillers, etc. Raw materials should be precisely proportioned according to the required adhesive properties and application.

Mix and heat

The process of mixing and heating raw materials heats the raw materials to a liquid state, usually at high temperatures. Mixing and heating ensure that the raw materials are fully dissolved and mixed to obtain a uniform hot melt adhesive.

Filter and remove impurities

Before proceeding to the next step, the hot melt adhesive is usually passed through a strainer or other filtration device to remove impurities and particles and ensure the quality of the product.

coating or spraying

Coating or spraying is a critical step in applying hot melt adhesive to a substrate. This can be accomplished by means of application rollers, spray heads, nozzles, or other suitable devices. The method of coating or spraying depends on product requirements and production line design.

Cooling and solidification

Hot melt adhesive applied to a substrate needs to cool and solidify quickly to ensure it bonds quickly. Cooling is usually achieved by cooling drums, air cooling or other cooling devices.

cutting and processing

The cooled strip hot melt adhesive can be cut, trimmed or processed as needed to prepare it into the required shape and size.

Packaging and storage

Prepared strip hot melt adhesive products need to be packaged to ensure that they maintain quality during transportation and storage. Proper packaging can also extend the shelf life of your product.

QC

Throughout the production process, quality control and testing are required to ensure that hot melt adhesive products meet specifications and performance requirements. This can include bond strength testing, viscosity testing, etc.

Records and Documentation

For quality traceability and management, key parameters and data during the production process need to be recorded. These records can help resolve potential quality issues and improve production processes.

Cleaning and maintenance

Regular cleaning and maintenance of production equipment is very important to ensure the stability and reliability of the production process.

These steps cover the main aspects of the strip hot melt adhesive production process. Specific production line design and process parameters will vary based on product type, use and size. Therefore, when establishing a hot melt adhesive production line, it needs to be customized and adjusted according to specific conditions.

CN

CN

HOME

HOME Why is Sigma Blade Mixer so popular? | JCT Machinery

Why is Sigma Blade Mixer so popular? | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address