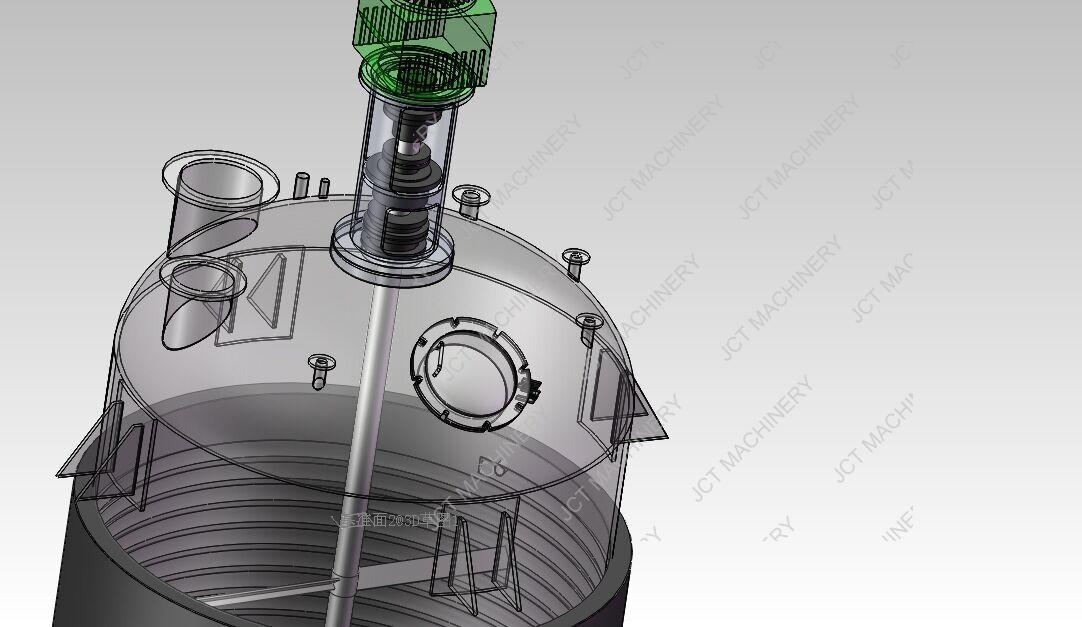

General Description of JCT hot melt tank:

1). Different capacity design from 50L to 50,000L.

2). Made of stainless steel 304/ 316L, or other material (decide by client).

3). Have jacket and coil-pipe style.

4). Vacuum and high-pressure are available.

5). Super mixer for most chemicals / food materials mixing and reacting.

6). Widely used in producing resins, adhesives, paints, cosmetics, pharmaceuticals and other chemical productions.

7). Can be heated by oil or water or steam, temperature range: 0 - 500 centigrade.

8). With different mixing paddles, can be designed as requirements.

9). Supply whole production line for different products, also including producing technology.

We can supply production line range of JCT hot melt tank:

1.Alkyd resinproduction line

2.Unsaturated resin production line

3.Acrylic resin production line

4.Urea-formaldehyde resin production line

5.Polyurethance resin prodcution line

6.Epoxy resin production line

7.Silicone sealant production line

8.White latex glue production line

9.Hot melt glue production line

10.Acrylic sealant production line

11.Paint production line

12. Super glue production line

13.Silicone rubber production line

How to select the appropiate machine

Take a example by the FYF-1000

FYF means the reactor kettle series(mainly for liquid, solvent making industry), 1000 means the design volume is 1000liters. The effect volume is about 80% of the tank, that means 800 liters/batch.

The daily production capacity depends on the reacting time.

Our services

The JCT hot melt tank applies for:

1). Resin:

Alkyd resin, epoxy resin, phenolic resin, acrylic resin...

2). Glue/ Adhesive:

Hot melt glue/ adhesive, grafted glue, white glue, silicone glue, all-purpose glue, PVC glue, PVA...

3). Others:

Paint, pigment, PVC, PVA, PVAC, PU, acrylic acid, and other latex, emulsion and liquid glue and adhesives.

1)Equipment volume: 20-50000L (volume in accordance with the requirements of the

design.)

2 ) Reaction temperature : -20℃~300℃。

3 ) Reaction pressure -0.1~1.6Mpa.

4 ) Equipment Material : SS304 , SS321 , SS316L stainless steel ; Q235-B carbon steel.

5 ) Mixing type: blade type, anchor type, frame type, screw belt type, turbine type,

dispersing disc type, combination type and so on.

6 ) Heating method: the heat conduction oil circulation heating, Electric heating in jacket,

steam heating, hot water heating.

7) Transfer structure: the outer jacket, the outer half tube, inner tube.

Contact information:

If you need to know the detailed equipment configuration, production technology, production

process, please contact us.

Email:[email protected]

Mobile: 0086-181 3837 3963(WhatsApp, Wechat)

Address: Donglian Jincheng Industrial Zone, Danzao Town, Nanhai, Foshan, Guangdong, China.

Product line

Product line sigma mixer

sigma mixer mixing tank

mixing tank Ribbon blender

Ribbon blender kneading machine

kneading machine Reactors

Reactors High-Shear Mixers

High-Shear Mixers

CN

CN

HOME

HOME

Related Suggestion

Related Suggestion

Jul 25,2024

Jul 25,2024

Tel

Tel

Email

Email

Address

Address