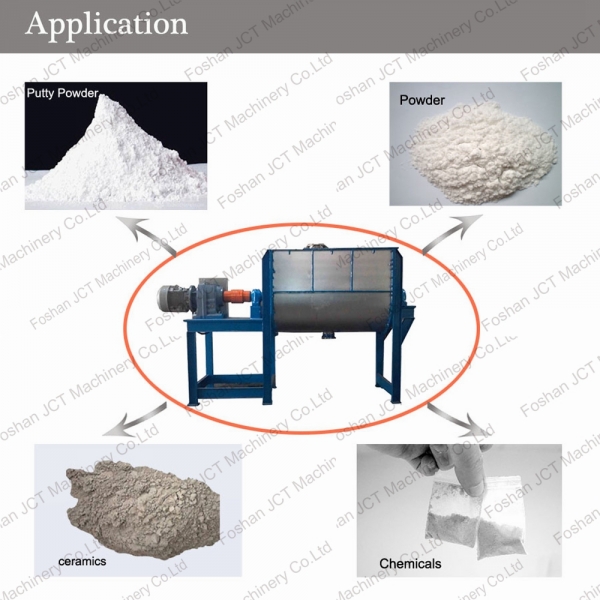

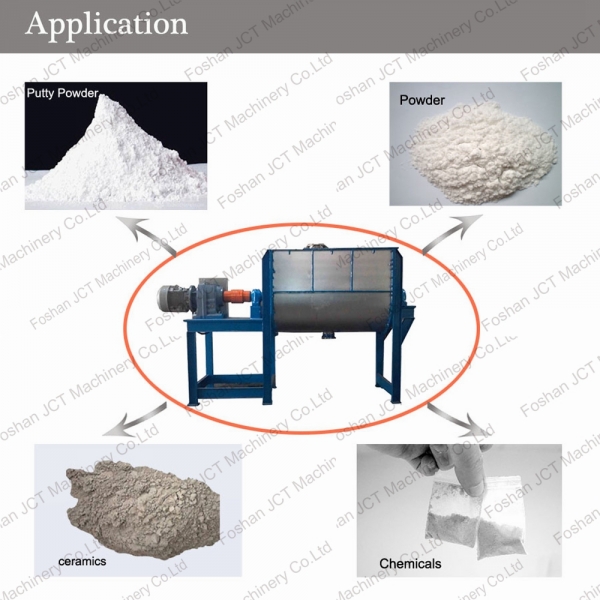

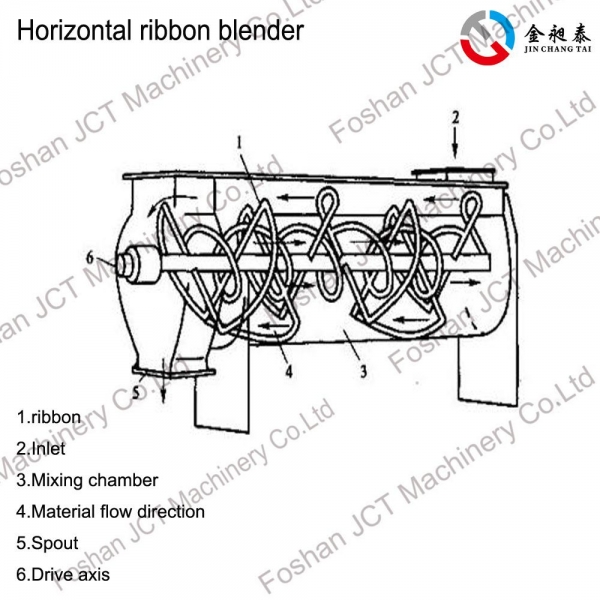

A. The introduction of The horizontal ribbon blender:

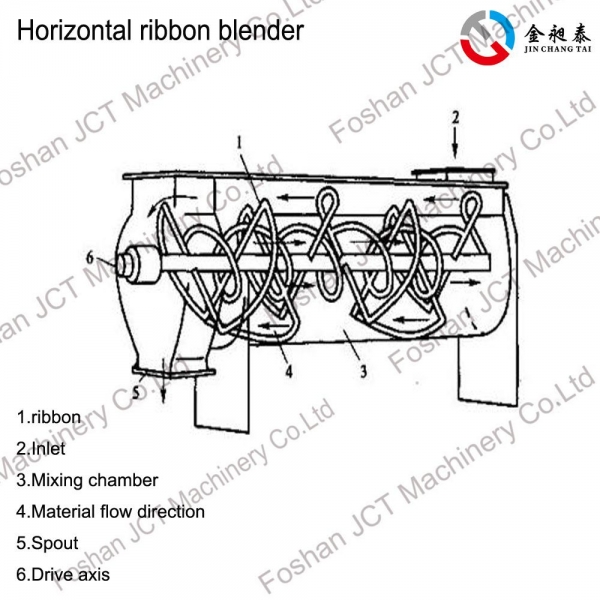

1.The horizontal ribbon blender consists of U-shaped containers, ribbon mixing blaze and transmission components; ribbon points continuous and disconnect the helical ribbon blaze is generally made of a double or triple outer spiral the materials from both sidesbrings together the central inner spiral the material transported from the center to the sides to from a stream mixed.

2.Adding a liquid and pasty materials mixed in the ribbon mixer for viscous or cohesive granule mixing and granule has a good effect, cylinder cover can be made of a wide-open door, so that the equipment for cleaning.

3.Can be added to the mixer barrel outer jacket,cooling or heating of the material is achineved by injecting the cooling medium to the jacket;

4.Discharge generally in the form of a pneumatic flap valve(manual), the arc valve compact embedding barrel, flush with the tube wall, the phenomenon of materila accumulation and mixing dead ends, reliable trim seal, frequent switch leakage.

B. The Features:

1) With large loading coefficient,the equipment covers in small area.

2) It's difficult to clean for mixing the sticky or cohesive materials.

C. The Work characteristics:

1) The horizontal ribbon mixer is friven by a motor through a reduction of the special arrangement of ribbon spindle rotation.outer ribbon put the material to the centerof machine, inner ribbon push the material to a certain position or plates,both of them can make materials to mutual diffusion,convection, shear, dislocation and radial movement,to achieve a steady mixing performance in a short time.

2) There are three stirring way with standard design.continuous ribbon,Interrupter ribbon,and blaze can be chosen,they were arranged on the requirements of the center or bottom discharge materials.

D. The discharge structure:

With the discharge form of manual flap valve, the arc valve is tightly embedded inner cylinder, without dead

material accumulation and mixing phenomenon. Reliable edge of the seal, ensure frequent leaks at the beginning

Contact information:

If you need to know the detailed equipment configuration, production technology, production

process, please contact us.

Email:[email protected]

Mobile: 0086-181 3837 3963(WhatsApp, Wechat)

Address: Donglian Jincheng Industrial Zone, Danzao Town, Nanhai, Foshan, Guangdong, China.

Product line

Product line sigma mixer

sigma mixer mixing tank

mixing tank Ribbon blender

Ribbon blender kneading machine

kneading machine Reactors

Reactors High-Shear Mixers

High-Shear Mixers

CN

CN

HOME

HOME

Related Suggestion

Related Suggestion

Jul 25,2024

Jul 25,2024

Tel

Tel

Email

Email

Address

Address