What is the key features and components of a sigma mixer?

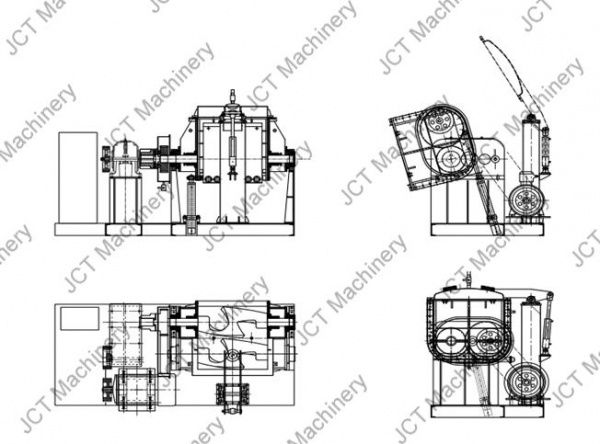

Dual Mixing Blades: The sigma mixer features two horizontally oriented, sigma-shaped blades that rotate in opposite directions. These blades resemble the Greek letter "sigma," which gives the mixer its name.

Trough or Bowl: The mixing chamber of the sigma mixer is typically a trough or bowl-shaped vessel where the materials are loaded for mixing. The dual blades rotate within this chamber, ensuring thorough mixing and kneading.

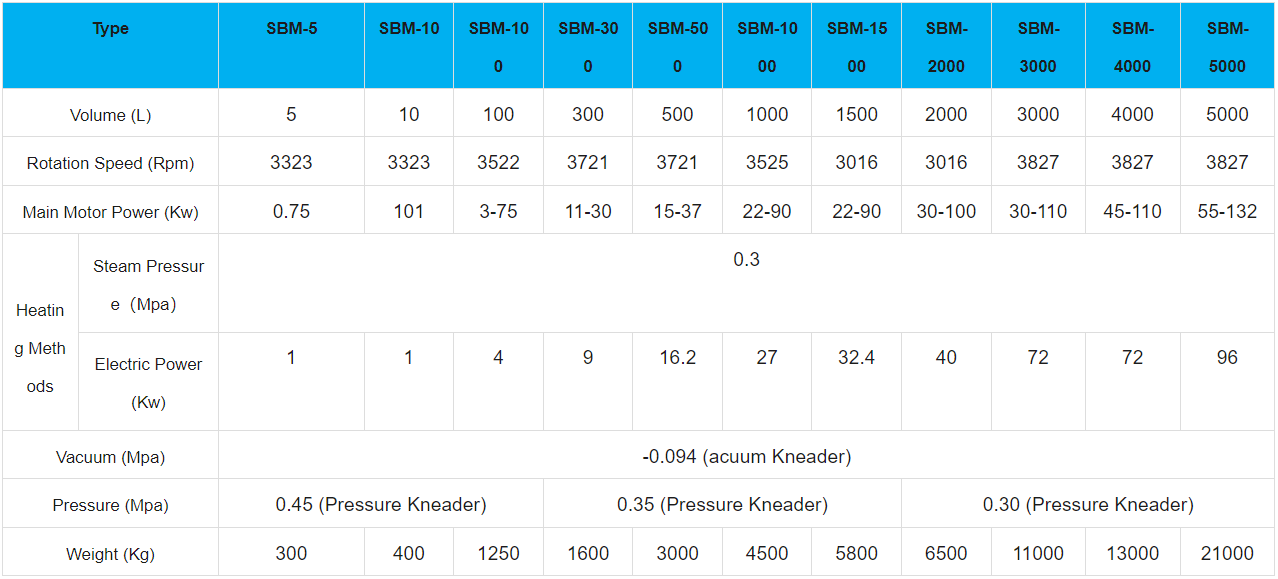

Cooling or Heating Jackets: Some sigma mixers are equipped with cooling or heating jackets around the mixing chamber. These jackets allow for precise temperature control during mixing processes that involve temperature-sensitive materials.

Control System: Modern sigma mixers often include control systems that allow operators to adjust the mixing speed, direction of rotation, and other parameters for optimal mixing performance.

What is the working principle of sigma mixer?

Kneading and cutting: The relative movement of the sigma mixer's 2 blades triggers the kneading, cutting and folding of the material. This action mixes the different material components together, ensuring even dispersion.

What is the benefits of using sigma mixer?

Effective Mixing: The dual-blade design and kneading action ensure thorough and consistent mixing even for high-viscosity materials.

Heat Transfer: Cooling or heating jackets allow for precise temperature control during mixing processes.

Versatility: Sigma mixers can handle a wide range of materials, from sticky pastes to dry powders.

Applications:

Dough Mixing: Sigma mixers are commonly used in the food industry for kneading dough for bread, pasta, and various baked goods.

Rubber and Plastics: They are used to mix rubber compounds, polymers, and other high-viscosity materials in the rubber and plastics industries.

Pharmaceuticals: Sigma mixers can be employed for blending and mixing pharmaceutical powders, pastes, and formulations.

Chemicals: They are suitable for mixing adhesives, resins, sealants, and other chemical compounds.

Cosmetics: Sigma mixers are used in the cosmetics industry for blending creams, lotions, and other cosmetic products.

Contact information:

If you need to know the detailed equipment configuration, production technology, production

process, please contact us.

Email:[email protected]

Mobile: 0086-181 3837 3963(WhatsApp, Wechat)

Address: Donglian Jincheng Industrial Zone, Danzao Town, Nanhai, Foshan, Guangdong, China.

Product line

Product line sigma mixer

sigma mixer mixing tank

mixing tank Ribbon blender

Ribbon blender kneading machine

kneading machine Reactors

Reactors High-Shear Mixers

High-Shear Mixers

CN

CN

HOME

HOME

Related Suggestion

Related Suggestion

Jul 25,2024

Jul 25,2024

Tel

Tel

Email

Email

Address

Address