Equipment For Bulk Hot Melt Glue Production | JCT Machinery

Jul 03,2024

Jul 03,2024

JCT

JCT

When customers want to produce hot melt glue sticks or granule, JCT Machinery will recommend reactors to customers. However, bulk hot melt glue is usually produced using sigma mixer rather than reactor due to its high viscosity and special process requirements.

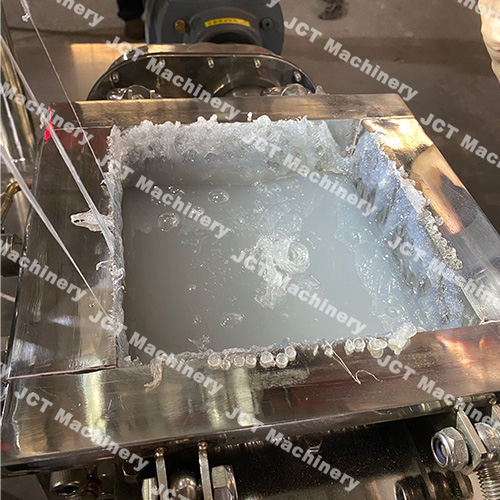

Customers came to JCT factory to try 5L sigma mixer

1. High Viscosity Material Processing

Advantages of Sigma Mixer:

- Strong Mixing and Shearing Force: Sigma mixer is designed with two intermeshing blades, which can generate strong shearing force and mixing effect, and is particularly suitable for processing high viscosity materials, such as bulk hot melt glue.

- Uniform Mixing: The design of sigma mixer ensures that the materials can be evenly mixed under high viscosity conditions, avoiding problems such as uneven ingredients and incomplete mixing.

Disadvantages of Reactor:

- Low Mixing Efficiency: The agitator of reactor is usually suitable for liquid or low-viscosity materials. For high-viscosity bulk hot melt glue, the mixing effect is poor.

- Difficult to Disperse Evenly: High-viscosity materials are easy to accumulate and form dead corners in reactor, resulting in uneven mixing.

2. Heat Transfer

Advantages of Sigma Mixer:

- Efficient Heat Conduction: Sigma mixer is usually equipped with a jacket or built-in heatting device, which can effectively control the temperature of the mixture and ensure that bulk hot melt glue is processed at a suitable temperature.

- Uniform Heating: The paddle movements of sigma mixer makes the material tumble continuously, ensuring uniform heat distribution and preventing local overheating or overcooling.

Disadvantages of Reactor:

- Uneven Heat Transfer: Due to the limited stirring effect of reactor, the heat transfer efficiency of high-viscosity materials is low, which is prone to local overheating or uneven cooling.

- Difficult Temperature Control: For high viscosity materials, temperature control in reactor is more difficult, which may affect the quality and performance of hot melt glue.

3. Process Requirements

Advantages of Sigma Mixer:

- Adaptable to Various Processes: Sigma mixer can perform various operations such as heating, cooling, exhausting, etc. during the mixing process to meet the various process requirements of bulk hot melt glue production.

- Efficient Degassing: Sigma mimxer can effectively remove bubbles in the material under high viscosity conditions and improve the purity and performance of hot melt glue.

Disadvantages of Reactor:

- Process Limitations: Reactor is mainly used for reaction and heating, and it is difficult to perform multiple process operations at the same time, especially the degassing and homogenization of high viscosity materials.

4. Production Efficiency

Advantages of Sigma Mixer:

- Efficient Production: The high shear force and efficient mixing ability of sigma mixer can greatly shorten the mixing time and improve production efficiency.

- Reduced Cleaning and Maintenance Time: The design of sigma mixer is easy to clean and maintain, reducing downtime and improving the overall efficiency of the production line.

Disadvantages of Reactor:

- Inefficient Production: When reactor handles high viscosity materials, the mixing time is long and the production efficiency is low.

- Difficult Cleaning: It is difficult to clean the high-viscosity materials in reactor, which increases maintenance and downtime.

JCT Machinery now have 5L laboratory sigma mixer in stock, which can be ship within 1 week. Contact us for detail informations. (also have 5L planetary mixer)

CN

CN

HOME

HOME MS Glue Production Line | JCT Machinery

MS Glue Production Line | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address