1.Production Process of JCT silicone based adhesives production line:

A. Basic material production system: Put the 103 glue and other material into the Kneading machine, operating with Heat transfer oil heating system and Vacuum system, mixing about four to five hours.

B. Basic material milling system: After the Basic material production system, use a Pump to transfer the material into the Three-roll milling machine, and get the semi-finished sealant.

C. Silicone sealant making system: Add other raw materials, colors and mix with the semi-finished sealant in the Dispersing Machine, and then stir more than one hour to get the finished silicone sealant.

D. Packing system: Using the Hydraulic Discharge Machine to press out the silicone sealant, and then packing by the Semi-rigid Tube Filling Machine.

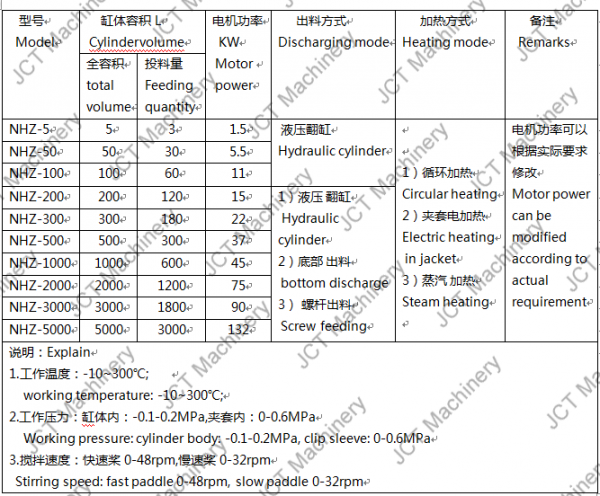

2. The specification:

JCT silicone based adhesives production line

1. Oil/ Steam/ Electric heating

2. SS304 or SS306

3. Water cooling

4. CE, ISO9001

3.The Blazes of kneading machine:

4.What is kneading machine in JCT silicone based adhesives production line?

1)The Dispersion Kneader Machinery_Kneader Extruder is a high viscosity elastic plastic material mixing, kneading, broken and

scattered, and the ideal equipment for the aggregation, with advantages of mixing and kneading high efficiency;

2)Mixing method: using two different speed propeller (Z type or ∑type) strong extrusion, shear, the materials are mixed uniformly;Dispersion

3)Kneader can be divided into the vacuum type, pressure type, pressure type ;

4)Heating cooling method: heat conduction oil heating, jacket electric heating, steam heating, water cooling, etc.;

5)Open cover: hydraulic open cover.Dispersion Kneader Machinery_Kneader Extruder

6)Discharging mode: hydraulic dump cylinder dump, bottom discharging, screw extrusion, etc.

7)be installed on the device a variety of safety, measurement, control and instrumentation.

8)The parts contact with material are made of stainless steel material, can also be in accordance with the requirements of the buyer;

9)the shaft seal is sealed with vacuum structure. To prevent the sealing filler particles into the cylinder,it can ensure the quality and purity of the material.

Usage of JCT silicone based adhesives production line:

A. Neutral Silicone Sealant: used for filling and sealing in Metal, glass, mirror, glass window, aluminium products, PMMA, silicone resin, vulcanizing silicone rubber, ceramics, natural and synthetic fiber, concrete, cement, marble, steel, etc.

B. Acid Silicone Sealant: used for filling and sealing in all kinds of interior decoration of car, nameplate, plastic material, pipe joints, glass, glass window, etc

Contact information:

If you need to know the detailed equipment configuration, production technology, production

process, please contact us.

Email:[email protected]

Mobile: 0086-181 3837 3963(WhatsApp, Wechat)

Address: Donglian Jincheng Industrial Zone, Danzao Town, Nanhai, Foshan, Guangdong, China.

Product line

Product line sigma mixer

sigma mixer mixing tank

mixing tank Ribbon blender

Ribbon blender kneading machine

kneading machine Reactors

Reactors High-Shear Mixers

High-Shear Mixers

CN

CN

HOME

HOME

Related Suggestion

Related Suggestion

Jul 25,2024

Jul 25,2024

Tel

Tel

Email

Email

Address

Address