High quality pressure tank high pressure reactor autoclave made in china

Reactor is main machines used for resin,adhesive,silicone oil making, Following are the main features.

1. Operating principle: Break down or recombined the materials through mixing, filling and cooling, to

promote the reaction of polymerization.

2. Components: Body, gears, mixing devices, heating devices, cooling devices, seal, etc.

3. Auxiliary Equipment:Distillation column, head tank,condenser,water separator,collecting cans, filters, etc..

4. Applicable Field: All the liquid-liquid, liquid-powder reaction industry.

|

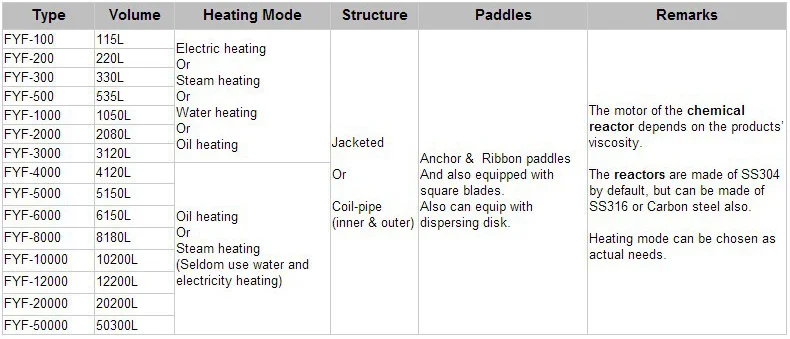

Technical Parameters

|

|||

|

Applications

|

|||

Reactor is widely used in resins, adhesives, paint, cosmetics, pharmaceutical and other chemical

production.

|

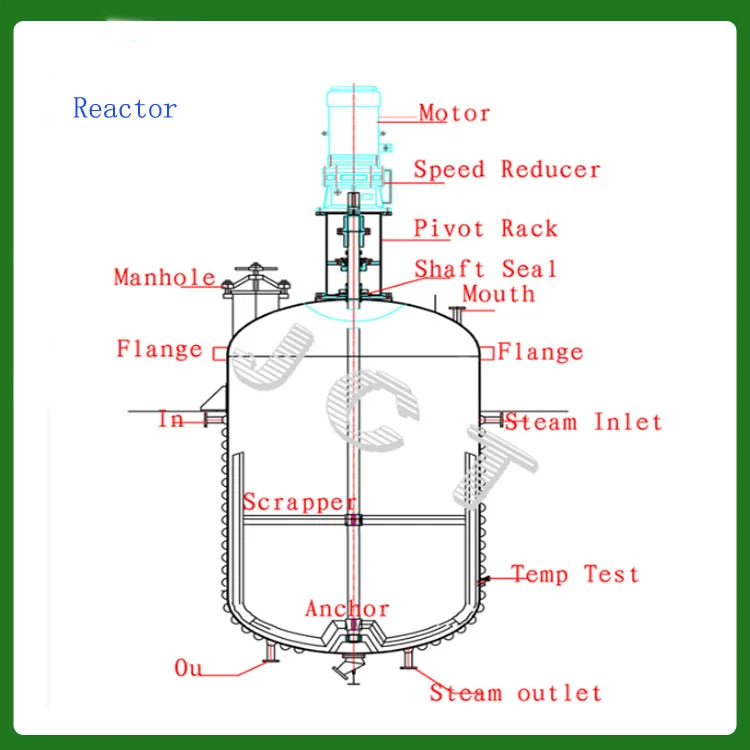

Main parts

|

|||

|

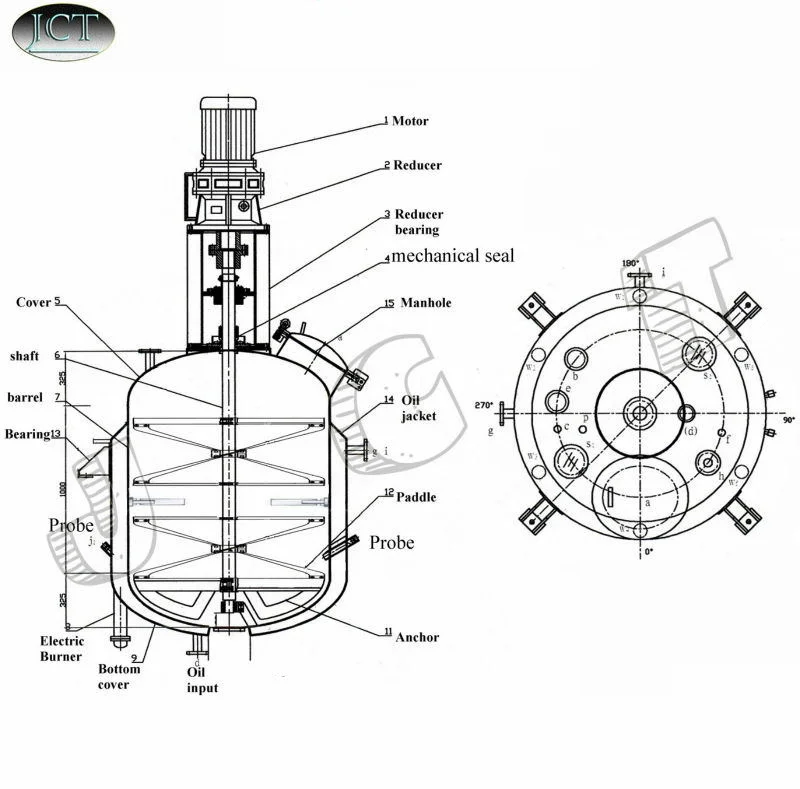

Design Drawings

|

|||

Q:After buying the equipments, I don\'t know how to design the plant and install the equipments?

A: Don\'t worry! These pictures are our real engineering case. Our company has a professional team of engineers to design plant for you. About the installation, our engineers available to service machinery overseas After-sales Service if you need. Our company can provide one-stop service and guarantee your satisfaction.

Foshan Jin Chang Tai Machinery Co., LTD. is a modern high-tech private enterprise with R&D design, manufacturing, installation and commissioning, after-sales service. Specializing in the producing various types of stirring, mixing, dispersing and response equipment.

Our clients

JCT\'s main markets: China, Europe, Africa, Middle East, South America, South Asia and so on.

Our products are sold to more than 150 countries and regions around the world.

Our team

A 8-experienced-engineer designing team +

A 35-skilled-technician team +

A 15-passionate-sales team =

make up the JCT powerful team.

Certifications

JCT was set up at 2004, through about 10 years\' endeavor, our products has been all over the world. In the industry we have a good reputation and won many prizes. What\'s more, we have edged ourselves into the top 5 in China.

Work shop

Our company has more than 20 years experience to research and manufacture the MIXING MACHINE and REACTOR.

Rich experience and professional manufacturing to ensure the products of excellent quality.

Q: Can you send the formula for the products we want to make?

A: Our machines can be used for many kinds of product making, such as Resin, Paint, Adhesive, Cosmetic, Food, Chemicals. There are many kinds of these products, so it\'s impossible for us to know all the formulas and technologies. We can assist you to find the raw material list you need, and after you place order with us, we can help you to find formula and technology, there will be engineers to teach you how to make the product, and the cost will be on your account.

Q: Do you have machines in stock?

A: Yes, but just the small-scale machines. Machines are different with other products, most of the large-scale machines are designed according to our customers\' requirements, different customers have different production requirements, so the technical parameter is different for most machines. On the other hands, most of the our machines will cover a large area, so once the machines are finished, we will effect shipment after QC.

Q: Why does it take at least 20 days to finish the machine?

A: Once receipt the deposit from you, we will design the drawings and make out the list of the materials and accessories for the production. Once the drawings are finished, our workers will start the production, from welding, polishing, assembling, debugging, detection and so on. After finish, they need time to check the machines, if found any possible defect parts, they will return to the production until every part is 100% approved.

Please feel free to contact us by email or the form below, we will soon reply within 24 hours.

- Mold glue production line

- Paint production line

- Neoprene adhesive production line

- Liquid silicone rubber production line

- Complete production equipment of Alkyd resin

- Acrylic emulsion production line

- vulcanized silicone rubber production line

- Graft adhesive production line

- Hot melt adhesive production line

- Silicone sealant production line

Related Suggestion

Related Suggestion

● Paint Mixer Blade | JCT Machinery

Jul 22,2024

Jul 22,2024

Tel

Tel

Email

Email

Address

Address

Donglian Jincheng Industrial Zone, Danzao Town, Nanhai District, Foshan City, Guangdong Province, China

- Contact us

Donglian Jincheng Industrial Zone, Danzao Town, Nanhai District, Foshan City, Guangdong Province, China

Donglian Jincheng Industrial Zone, Danzao Town, Nanhai District, Foshan City, Guangdong Province, China

- Equipments

- Product line

- sigma mixer

- mixing tank

- Ribbon blender

- More +

- Links

- jctmixing

- jctmixingequipment

- Share us

CN

CN

HOME

HOME