1. Shape Design

- Twisted Blade : Usually spiral, similar to the shape of twist. This design can generate strong shear force during mixing, which helps to mix the materials evenly.

- Folding Blade : It is usually flat, with a certain angle and folding. This design can generate thrust and squeeze the material.

2. Mixing Effect

-

Twisted Blade : It is suitable for high-viscosity and high-solid content materials, which can effectively push the materials in different directions so that they can be fully mixed in a short time. Twisted blade can better bring the materials from the bottom of the mixing cylinder to the top and redistribute them to avoid dead corners.

-

Folding Blade : It usually used for medium-viscosity materials, mainly used to push and flip the materials to form a better circulation flow and ensure that the materials are mixed evenly. Folding blade can produce a gentler mixing effect during operation and is suitable for shear-sensitive materials.

3. Applicable Scenarios

-

Twisted Blade : It is more suitable for the production of high-viscosity products, such as pastes, silicone sealants, lithium battery slurry, etc. Due to its efficient mixing ability, it is particularly suitable for mixing tasks that require strong shear force.

-

Folding Blade : It is more suitable for low to medium viscosity materials, such as coatings, adhesives, liquid silicone and other products. Folding blade can provide sufficient mixing effect in these applications while avoiding excessive shearing of materials.

4. Shear Force

-

Twisted Blade : It provides high shear force, can break up agglomerated materials, and is particularly suitable for mixing systems with high solid content.

-

Folding Blade : The shear force is relatively low, suitable materials that need to be gently mixed to prevent the material from being over-handles.

5. Material Flow

-

Twisted Blade : It can produce complex flow patterns during the mixing process, which helpd to evenly disperse the material throughout the mixing cylinder.

-

Folding Blade : It mainly pushes and flips the material to form an up and down circulation flow pattern.

Twisted Blade: more suitable for mixing materials with high viscosity and requiring strong shear force, and can effectively handle viscous and easily agglomerated materials.

Folding Blade: More suitable for mixing medium and low viscosity materials, suitable for even mixing and material circulation, and not easy to damage the structure of the material.

Contact information:

If you need to know the detailed equipment configuration, production technology, production

process, please contact us.

Email:[email protected]

Mobile: 0086-181 3837 3963(WhatsApp, Wechat)

Address: Donglian Jincheng Industrial Zone, Danzao Town, Nanhai, Foshan, Guangdong, China.

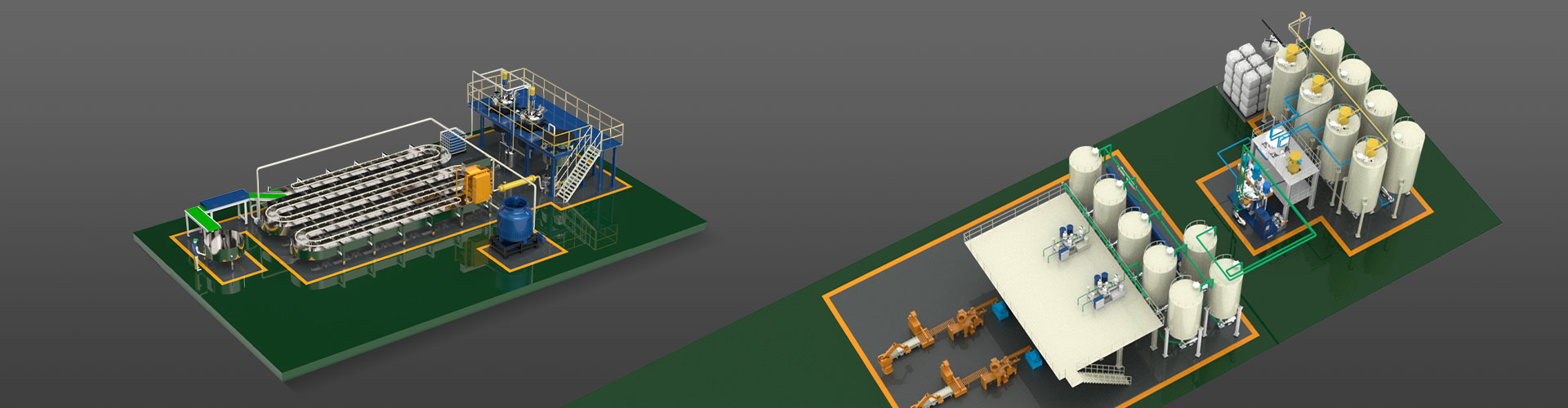

Product line

Product line sigma mixer

sigma mixer mixing tank

mixing tank Ribbon blender

Ribbon blender kneading machine

kneading machine Reactors

Reactors High-Shear Mixers

High-Shear Mixers

CN

CN

HOME

HOME

Related Suggestion

Related Suggestion

Jul 25,2024

Jul 25,2024

Tel

Tel

Email

Email

Address

Address