Double Planetary Mixer Working Principle

The core of double planetary mixer is two sets of independent mixing blades, which not only rotate around their own axes, but also revolve around the center of the mixing tank along a common orbit. This design ensures that the materials are fully mixed in the mixing tank, whether it is a high-viscosity material or a material containing multiple components, it can be mixed evenly.

Main Features of Double Planetary Mixer

1. Efficient Mixing

Due to the dual motion path of the blades, the mixing efficiency is extremely high, especially suitable for high-viscosity materials.

2. Uniform Dispersion

Double planetary mixer can fully disperse the components during the mixing process to ensure the uniformity of the mixture.

3. Vacuum Operation

Most double planetary mixers can work in a vacuum environment to remove bubbles in the mixture and improve product quality.

4. Temperature Control

The mixing cylinder is usually equipped with a jacket, which can control the material temperature by passing cooling or heating media to meet different process requirements.

For small-scale 5L double planetary mixer, click.

1. Mixing of High-viscosity Materials: polyurethane sealant, silicone sealant, etc.

2. Uniform Mixing of Multi-component Materials: composite materials, food ingredients, etc.

3. Materials that Need to Remove Bubbles: potting glue, thermal conductive materials, etc.

1. Volume of Mixing Tank: 5L-2200L (working volume 80%)

2. Motor Power: 1.1kW-90kW

3. Planetary Revolution Mixing Speed: 0-60rpm

4. Low Speed Autorotation Mixing Speed: 0-120rpm

5. High-speed Dispersion Mixing Speed: 0-1000 (1500)rpm

6. Working Pressure Range: -0.1~0.3MPa

7. Lifting Mode: Hydraulic lifting

8. Speed Regulation Mode: Frequency converter speed regulation.

9. Blade Type: Folding blades, twisted blades

Contact information:

If you need to know the detailed equipment configuration, production technology, production

process, please contact us.

Email:[email protected]

Mobile: 0086-181 3837 3963(WhatsApp, Wechat)

Address: Donglian Jincheng Industrial Zone, Danzao Town, Nanhai, Foshan, Guangdong, China.

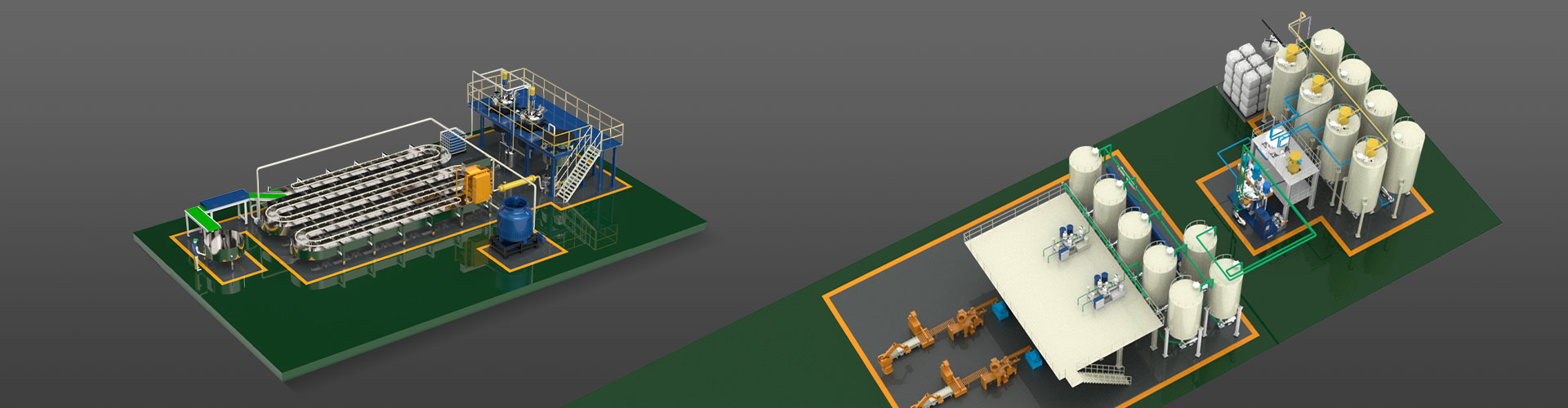

Product line

Product line sigma mixer

sigma mixer mixing tank

mixing tank Ribbon blender

Ribbon blender kneading machine

kneading machine Reactors

Reactors High-Shear Mixers

High-Shear Mixers

CN

CN

HOME

HOME

Related Suggestion

Related Suggestion

Jul 25,2024

Jul 25,2024

Tel

Tel

Email

Email

Address

Address