Equipment introduction:

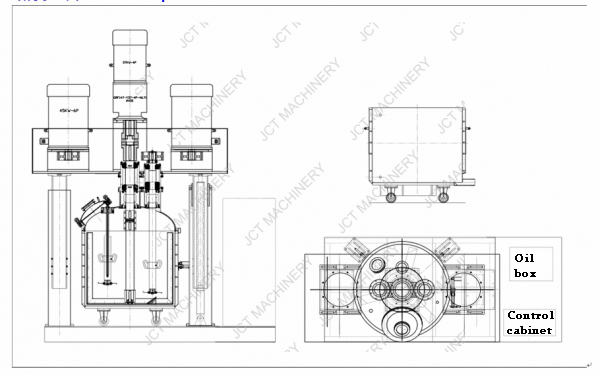

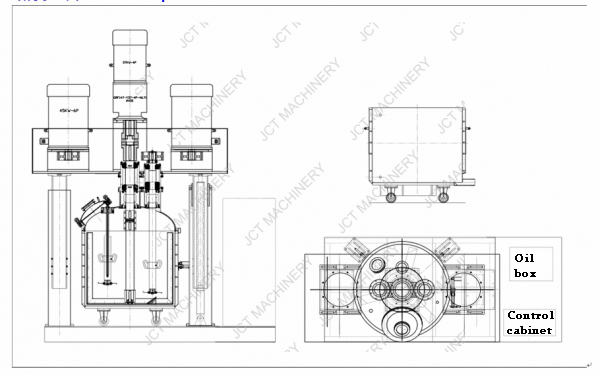

1) 500L High Speed Dispersion machine is a kind of highly efficient and versatile mixer with mixing

dispersing, cutting and mixing function.

2) There are three different types of planetary mixers in the blender. One of the groups of

agitator rotates around the central axis of the kettle body. The other two groups of mixing

device with different speed rotation speed. To make the material in the kettle for complex

movement, the material is strongly cut and mixed. In the equipment, '山' shape blade around

the axis of the kettle body rotation, on the cylinder wall and bottom material scraped off

and involved in mixing, mixing effect is more ideal.

3) In the form of the agitator, according to the matterial requirements can be designed as

a multi-layer blades, frame type, butterfly type,leaf type, etc.

4) The sealing performance of the equipment is good, it can be pumped vacuum, can exhaust

and eliminate the bubble inside the material.

5) The hydraulic lifting device of cylinder, the cylinder can move freely, the operation is

very convenient.

Chemical high shear and inline mixer is widely used in sealant, silicone rubber, adhesive, paste,

cosmetics, paint, ink, cell paste, food, and other industries.

|

Model

|

Cylindervolume(L)

|

Motorpower(KW)

|

Stirring speed(rpm)

|

Remarks

|

|

total volume

|

Feeding quantity

|

Low speed mixing

|

High speed dispersion

|

Low speed mixing

|

High speed dispersion

|

|

QF-5

|

5

|

4

|

0.75

|

0.75*2

|

23

|

0-1000

|

Table data for reference, actual data according to the specific process requirements, material viscosity, etc.

|

|

QF-20

|

20

|

16

|

1.1

|

1.1*2

|

23

|

0-1000

|

|

QF-50

|

50

|

40

|

1.5

|

2.2*2

|

23

|

0-1000

|

|

QF-100

|

100

|

80

|

3

|

5.5*2

|

23

|

0-1000

|

|

QF-200

|

200

|

160

|

4

|

7.5*2

|

23

|

0-1000

|

|

QF-300

|

300

|

240

|

5.5

|

15*2

|

23

|

0-1000

|

|

QF-500

|

500

|

400

|

7.5

|

22*2

|

23

|

0-1000

|

|

QF-1000

|

1000

|

800

|

18.5

|

30*2

|

0-20

|

0-1000

|

|

QF-2000

|

2000

|

1600

|

30

|

37*2

|

0-20

|

0-1000

|

|

QF-3000

|

3000

|

2400

|

30

|

45*2

|

0-20

|

0-1000

|

|

QF-4000

|

4000

|

3200

|

37

|

55*2

|

0-20

|

0-1000

|

|

QF-5000

|

5000

|

4000

|

45

|

55*2

|

0-20

|

0-1000

|

|

1、Lift mode: hydraulic lift

|

|

2、The mixing tank with a clip, can be heated and cooled according to the need;

|

|

3、Pressure range: -0.1~0.3MPa;

|

|

4、Speed control mode: frequency converter.

|

Contact information:

If you need to know the detailed equipment configuration, production technology, production

process, please contact us.

Email:[email protected]

Mobile: 0086-181 3837 3963(WhatsApp, Wechat)

Address: Donglian Jincheng Industrial Zone, Danzao Town, Nanhai, Foshan, Guangdong, China.

Product line

Product line sigma mixer

sigma mixer mixing tank

mixing tank Ribbon blender

Ribbon blender kneading machine

kneading machine Reactors

Reactors High-Shear Mixers

High-Shear Mixers

CN

CN

HOME

HOME

Related Suggestion

Related Suggestion

Jul 25,2024

Jul 25,2024

Tel

Tel

Email

Email

Address

Address