Ribbon Blender Blade Design | JCT Machinery

Dec 01,2023

Dec 01,2023

JCT

JCT

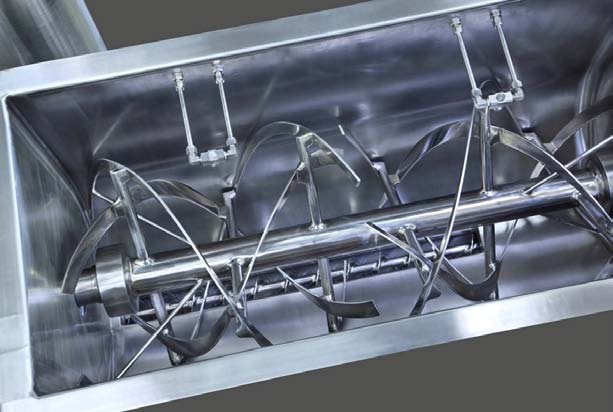

Ribbon blenders are commonly used in various industries for mixing dry powders, granules and other bulk materials. Ribbon blender blade design is crucial for achieving effecient and homogeneous mixing.

Ribbon Blender Blade Design

1. Ribbon Configuration

Ribbon blenders typically have two types of blades - inner and outer ribbons. The outer ribbon moves material in one direction, while the inner ribbon moves it in the opposite direction. This counter-current movement enhances mixing efficiency.

2. Blade Shape

Blades are often designed in a double-helix shape, resembling a ribbon. This shape promotes a three-dimensional flow of materials within the ribbon blender, ensuring thorough mixing.

3. Clearance

The distance between the blades and the blender's shell is essential. Adequate clearance is necessary to prevent material buildup and ensure a consistent mix. However, too much clearance can reduce mixing efficiency.

4. Blade Length

The length of the ribbon blender blade affects the intensity of mixing. Longer blades generally provide better mixing, but there's a balance to strike to avoid overloading the blender's motor.

5. Blade Thickness

Ribbon blender blade thickness influences the strength and durability of the blades. Thicker blades can withstand heavier loads but may require more power to operate.

CN

CN

HOME

HOME Grease Manufacturing Process | JCT Machinery

Grease Manufacturing Process | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address