Polyol Production Line Turnkey Project | JCT Machinery

Jul 12,2024

Jul 12,2024

JCT

JCT

What is polyol?

Polyols are organic compounds containiing multiple hydroxyl (-OH) groups and are one of the important raw materials for polyurethane production. They are mainly used to make foam plastics, elastomers, coatings, adhesives and sealants, and are widely used in industries such as construction, automobiles, furniture, footwear and electronics.

Polyol Production Line Equipment Configurations

1. Raw Material Storage and Delivery System

Function: Store and deliver various raw materials required for polyol production, such as ethylene oxide (EO), propylene oxide (PO), starters, catalysts, etc.

Equipment

- Storage tanks, hoppers

- Delivery pipelines, pumps, metering devices

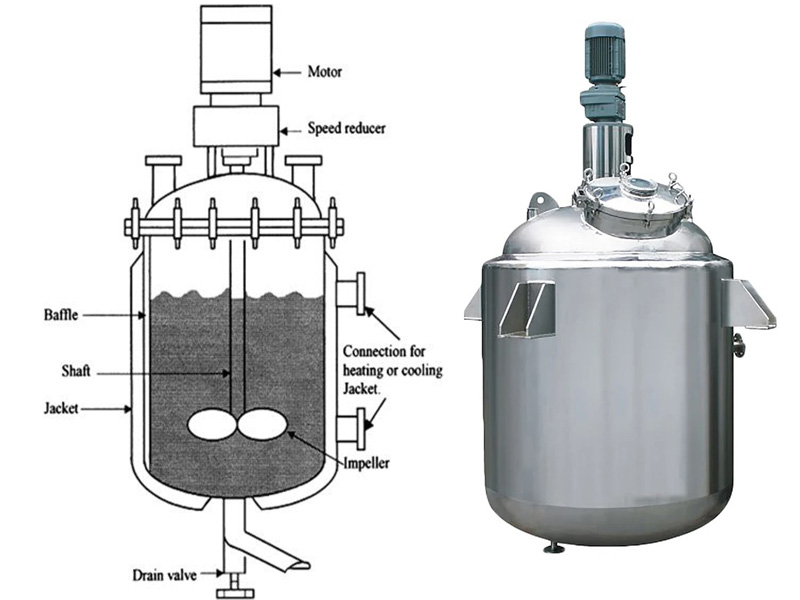

2. Reaction System

Function: Carry out polymerization reaction of EO and PO ith starters to generate polyols.

Equipment

- Reactor (with stirring, heating, cooling and pressure control functions)

- Reactor lining (corrosion-resistant material)

3. Refining System

Function: Remove by-products and unreacted raw materials generated by the reaction and purify the polyol products.

Equipment

- Distillation tower, evaporator

- Filter, separator

4. Distillation System

Function: Fracturation of polyols to separate polyols of different molecular weights to ensure product quality and specifications.

Equipment

- Distillation tower, reboiler, condenser

- Fractional column, collection tank

5. Dryinig System

Function: Remove moisture and volatile impurities from polyols to ensure the purity and stability of the product.

Equipment

- Vacuum dryer, spray dryer

- Dehumidification device

6. Packaging and Storage System

Function: Package and store the produced polyol products for easy transportation and sales.

Equipment

- Packaging machine, storage tank

- Automatic box packing machine, pallet

7. Process Control System

Function: Real-time monitoring and control of various parameters in the production process, such as temperature, pressure, flow, component concentration, etc., to ensure production stability and product quality.

Equipment

- PLC control system, DCS system

- Various sensors and testing instruments

8. Environmental Protection and Safety System

Function

- Treat waste gas , wastewater and solid waste generated in the production process to ensure environmental protection standards.

- Safety protection devices to prevent production accidents.

Equipment

- Waste gas treatment system, wastewater treatment system, solid waste treatment system

- Safety valve, explosion-proof device, leak detection system

CN

CN

HOME

HOME Silicone Sealant Production Line Automated System | JCT Machinery

Silicone Sealant Production Line Automated System | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address