Silicone Sealant Production Line Automated System | JCT Machinery

Jul 17,2024

Jul 17,2024

JCT

JCT

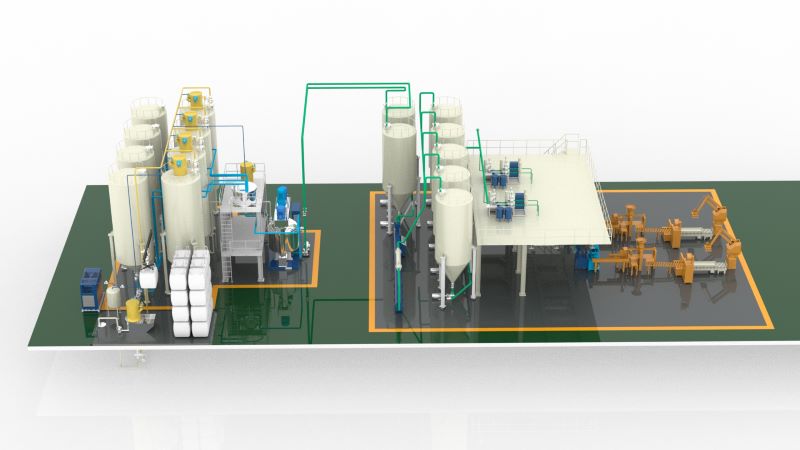

JCT Machinery provide automated silicone sealant production line turnkey project. We've been helped a lot customers to set up their production lines.

Why choose JCT Machinery?

Machines + Glue Formula + Help find raw materials suppliers

In the automated silicone sealant production line, automatically delivering materials from the powerful dispersing mixer to the press machine involves the coordination of a series of equipment and processes.

1. Discharge System of Powerful Dispersing Mixer

- Automatic Discharge Valve: Install an automatic discharge valve at the discharge port of the powerful dispersing mixer, and control the opening and closing of the discharge valve through PLC to realize automatic discharge of materials.

2. Conveying System

- Screw Conveyor: Use a screw conveyor to convey materials from the powerful dispersing mixer to the press machine. The screw conveyor is suitable for handling high viiscosity and paste materials, and has the characteristics of stable conveying and high efficiency.

- Pneumatic Conveying System: Suitable for long-distance conveying, the material is conveyed to the target location by compressed air. Pneumatic conveying pipelines and receiving hoppers need to be set up.

3. Intermediate Storage and Metering

- Intermediate Hopper: An intermediate hopper is set between the powerful dispersing mixer and press machine to temporarily store materials and accurately meter them through a weighing sensor.

- Automatic Metering System: The integrated weighing sensor ensures that the amount of material delivered to the press machine is accurate and consistent each time, avoiiding material waste or uneven production.

4. Feeding System of Press Machine

- Automatic Feeding Port: Set up an automatic feeding port on press machine, cooperate with the intermediate hopper and conveying system to realize automatic feeding of materials.

- PLC Control System: Control the feeding process through the PLC system, including monitoring the operating status of the conveyor, the material level of the hopper and the feeding amount of the press.

5. System Integration and Control

- PLC System: Integrate the control signals of all equipment to realize the automatic control and coordination of the entire production process. PLC system can program the operating parameters and logical relationships of each device.

- HMI Interface: Through the touch screen or computer interface, the operator can monitor and adjust the operating status and parameters of each device in real time to ensure the smooth operation of the silicone sealant production line.

- Sensor: Install temperature, pressure, liquid level and flow sensors to monitor the status of key points in real time to ensure the safety and stability of the production process.

6. Data Collection and Analysis

- MES System: Real-time collection and analysis of production data, such as material flow, production efficiency, equiipment status, etc., to conduct data analysis and optimize production processes.

CN

CN

HOME

HOME Paint Mixer Blade | JCT Machinery

Paint Mixer Blade | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address