Detail Introduction About Chemical Reactor | JCT Machinery

May 27,2024

May 27,2024

JCT

JCT

What Is Chemical Reactor?

Chemical reactor is a comprehensive reaction vessel that mainly realizes the heating, evaporation, cooling and low-speed mixing reaction functions required by the process. It is mainly used for liquid-liquid homogeneous reaction processes.

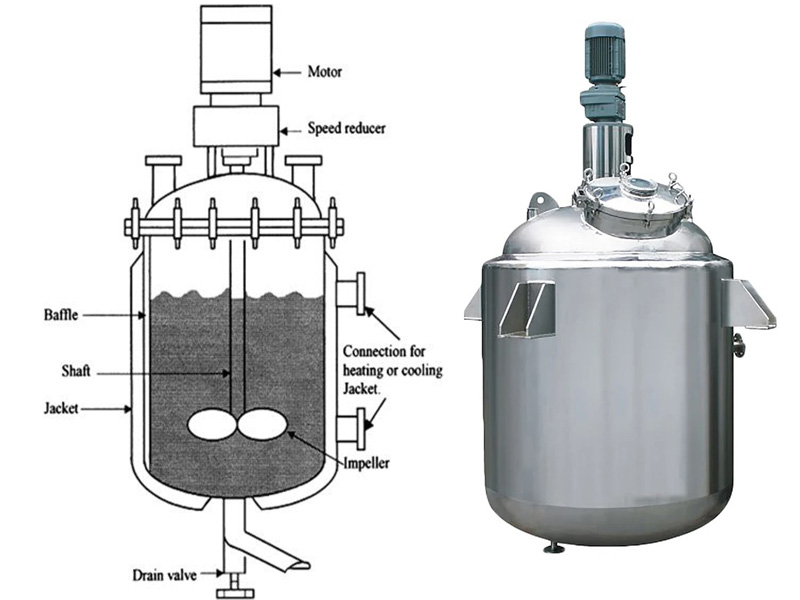

Main Structure of Chemical Reactor

Kettle body, kettle cover, jacket, stirrer, transmission device, shaft seal device, etc.

Material of Chemical Reactor

Generally, there are stainless steel, carbon manganeses steel, and other composite materials.

According to the material of the kettle body, chemical reactor can be divided into stainless steel reactor, carbon steel reactor, enamel reactor, steel-lined reactor, etc.

Selection of Chemicial Reactor Stirrer

Low Density Fluid: paddle, turbine, propelled, etc.

High Density Fluid: frame, anchor, propeller, etc.

Chemical Reactor Transmission Device

The transmission mechanism can use cycloidal pinwheel reducer, continuously variable speed rudecer or variable frequency speed regulation, etc., which can meet the special reaction requirements of various materials.

Precautions for Using Chemical Reactor

1. During normal operation, do not open the upper cover or touvh the terminals on the board to avoid electric shock.

2. Operation under pressure is strictly prohibited.

3. The heating speed should not be too fast, and the pressurization should be carried out slowly, especially the stirring speed, which is only allowed to rise slowly.

4. When the kettle body is heated to a higher temperature, do not come into contact with the kettle body to avoid burns. After the reaction is completed, the temperature should be cooled down first without rapid cooling to prevent damage caused by excessive temperature difference. At the same time, unplug the power supply in time.

CN

CN

HOME

HOME 10L Vertical Kneader Manufacturer | JCT Machinery

10L Vertical Kneader Manufacturer | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address