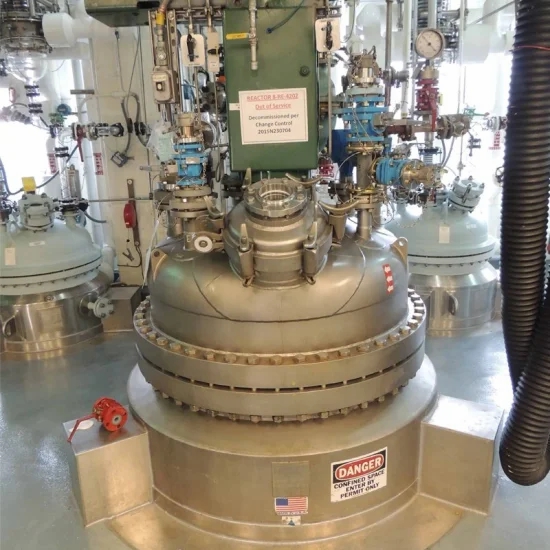

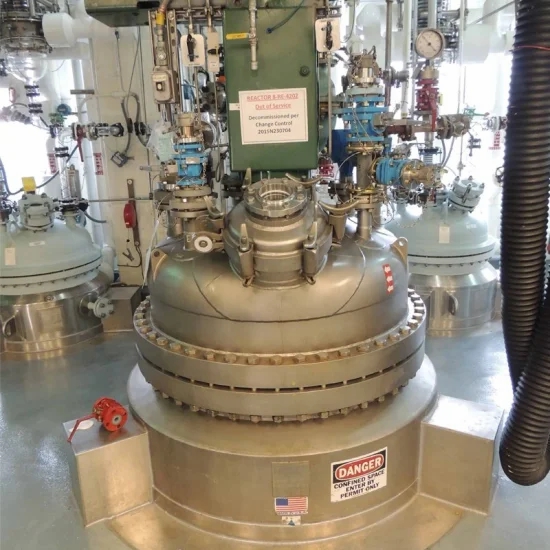

1.Production line equipment configuration:

Reaction kettle, condenser, dispersing kettle, filter, filling machine, steam furnace, water cooling system, material pump, Raw material tank,Finished storage tank,Metering tank,etc.

2. Advantages of Neoprene Adhesive Production Line:

1) Automation: Production lines are automated and can operate continuously with minimal human intervention. This results in higher production volumes and consistency.

2) Consistency and Quality Control: Production lines can maintain consistent product quality through precise control of raw material inputs and process parameters. Quality control measures are built into the process.

3) Efficiency: Production lines are designed for efficiency and can produce adhesive products at a faster rate compared to manual production. This can result in cost savings.

4) Scalability: Production lines can be scaled up or down easily to meet changing production demands. This flexibility allows for increased production capacity when needed.

5) Safety: Production lines can be designed with safety features to protect workers from potentially hazardous processes. They may also reduce the risk of workplace accidents.

Neoprene adhesive, also known as neoprene cement or contact adhesive, is a versatile adhesive known for its ability to bond a wide range of materials. Its primary application is in bonding or adhering materials together in a strong and durable manner. Here are some common applications of neoprene adhesive:

1. Footwear Manufacturing:

Neoprene adhesive is widely used in the footwear industry to bond the rubber soles to the shoe uppers. It provides a flexible and long-lasting bond that can withstand the rigors of walking and various weather conditions.

2. Automotive Industry:

Neoprene adhesive is used in automotive manufacturing for applications such as attaching weatherstripping, upholstery, and headliners to the interior of vehicles. It helps create a secure and airtight seal.

3. Woodworking and Cabinetry:

In woodworking and cabinetry, neoprene adhesive is used for laminating and bonding wood veneers, laminates, and plastic laminates to substrates like particleboard or MDF (medium-density fiberboard).

4. Marine Applications:

Due to its resistance to water and moisture, neoprene adhesive is suitable for marine applications. It can be used to bond materials on boats, such as rubber gaskets, seals, and insulation.

It's important to note that neoprene adhesive comes in various formulations, each designed for specific applications. Some formulations may have special properties such as high heat resistance, increased flexibility, or improved resistance to specific chemicals or environmental conditions. When selecting a neoprene adhesive, it's essential to choose the formulation that best suits the intended application to ensure a strong and reliable bond. Additionally, proper surface preparation and adhesive application techniques are critical for achieving the best results in any application.

Production line specifications:

1)500L-1500L Grafted adhesive production line;

2)2000L-3000L Grafted adhesive production line;

3)4000L-6000L Grafted adhesive production line;

4)8000L-12000L Grafted adhesive production line;

It can be designed according to the actual needs.

Contact information:

If you need to know the detailed equipment configuration, production technology, production

process, please contact us.

Email:[email protected]

Mobile: 0086-181 3837 3963(WhatsApp, Wechat)

Address: Donglian Jincheng Industrial Zone, Danzao Town, Nanhai, Foshan, Guangdong, China.

Product line

Product line sigma mixer

sigma mixer mixing tank

mixing tank Ribbon blender

Ribbon blender kneading machine

kneading machine Reactors

Reactors High-Shear Mixers

High-Shear Mixers

CN

CN

HOME

HOME

Related Suggestion

Related Suggestion

Jul 25,2024

Jul 25,2024

Tel

Tel

Email

Email

Address

Address