A mold glue production line typically refers to a manufacturing process or assembly line designed for the production of mold glue or adhesive used in mold-making applications. Mold glue, also known as mold adhesive, is a type of adhesive or bonding material that is used in the manufacturing of molds for various industries, such as the plastic injection molding industry or the metal casting industry.

Here's a simplified overview of what a mold glue production line might involve:

1. Raw Material Handling: The production line starts with the handling of raw materials. These raw materials could include various chemicals and compounds that, when mixed together, form the adhesive or glue. The specific composition of these materials would depend on the type of mold glue being produced.

2. Mixing and Blending: The raw materials are mixed and blended in precise quantities and under controlled conditions. This ensures that the adhesive's properties are consistent and meet the required specifications.

3. Chemical Reactions: Some mold glues may require chemical reactions to occur during the production process. These reactions might involve curing agents, catalysts, or other additives to achieve the desired properties, such as fast curing or high temperature

resistance.

4. Quality Control: Throughout the production process, quality control measures are in place to ensure that the adhesive meets the necessary standards. This may involve testing for properties like viscosity, strength, adhesion, and other relevant characteristics.

5. Packaging: Once the mold glue has been produced and passed quality control checks, it is typically packaged in containers suitable for distribution and use. Packaging may include bottles, drums, or other containers, depending on the intended market and application.

6. Distribution: The packaged mold glue is then prepared for distribution to customers, which can include manufacturers in various industries that use molds for their production processes.

7. Safety and Environmental Compliance: Depending on the nature of the adhesive and the location of the production facility, safety measures and environmental compliance protocols must be followed to ensure the safe handling of chemicals and the disposal of waste materials.

8. Maintenance and Cleaning: Regular maintenance and cleaning of production equipment are crucial to ensure the consistent quality of the mold glue and the efficient operation of the production line.

Keep in mind that the specific details of a mold glue production line can vary widely based on the type of adhesive being produced, the scale of production, and the technological sophistication of the manufacturing process. Additionally, advancements in adhesive

technology and manufacturing processes may lead to variations and improvements in mold glue production lines over time.

After the liquid silica gel is made into a mold, various liquid materials can be poured into the mold to form: for example, wax resin, cement, plaster, soap, etc., to replicate anything that has a solid body.

1. Features of silicone production line

1) Foshan Nanhai Jinchangtai Machinery Equipment Co., Ltd. is a manufacturer of chemical machinery and equipment for research, development, design, manufacturing, installation and commissioning. It has more than 15 years of experience in the design and manufacture of liquid silicone production equipment.

2) The liquid silicone equipment produced by Jinchangtai Machinery Equipment Co., Ltd. has the characteristics of advanced design and sophisticated manufacturing, reasonable structure, convenient operation, low labor cost, high production efficiency, and good product quality. It is suitable for all kinds of liquid silicone.

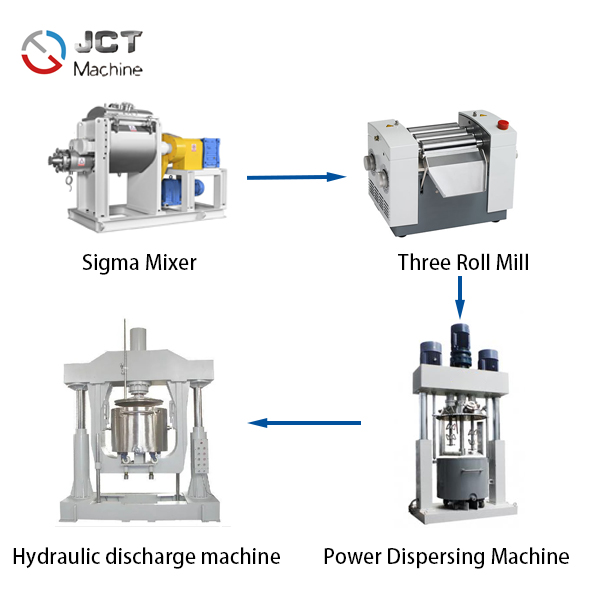

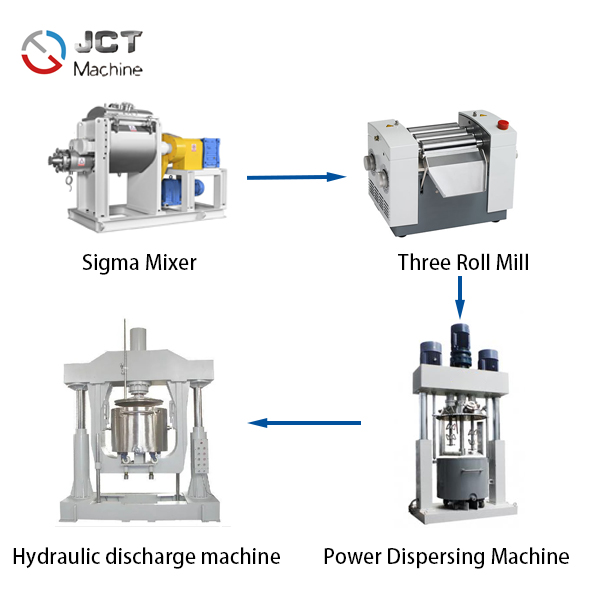

2. Equipment configuration of liquid silicone production line

1) Vacuum kneader;

2) High viscosity pump,

3) Base material storage tank,

4) Heating system (according to actual needs),

5) Vacuum system,

6) Three-roll mill,

7) Multifunctional dispersing mixer or planetary mixer,

8) Hydraulic discharge machine,

9) Cooling system.

3. Production process of liquid silica gel:

1) The preparation of raw materials is carried out according to the formula. Add the kneader, and the powder raw materials should be added several times and mixed evenly. Heating and heating, start the vacuum system, draw moisture from the material.

2) The base material reaches the base material storage tank through a high-viscosity pump, and these materials are slowly added to the three-roll grinder to meet the fineness requirements.

3) After grinding the substrate, put the material into the mixing drum. Then add other ingredients and paste.

4) Push the mixing drum into the multifunctional dispersing machine or planetary mixer to start mixing and high-speed dispersion. At the same time, the vacuum system is activated to extract moisture and air from the material. Start the cooling system to control the temperature of the material.

5) After the production is completed, push the mixing cylinder into the hydraulic discharge machine and divide it into packaging drums.

6) Pack the finished product into the warehouse.

1) 10-30 tons/mmonth mold glue production line;

2) 20-60 tons/month mold glue production line;

3) 40-120 tons/month mold glue production line

4) 60-180 tons/month mold glue production line

It can be designed according to the act

Contact information:

If you need to know the detailed equipment configuration, production technology, production

process, please contact us.

Email:[email protected]

Mobile: 0086-181 3837 3963(WhatsApp, Wechat)

Address: Donglian Jincheng Industrial Zone, Danzao Town, Nanhai, Foshan, Guangdong, China.

Product line

Product line sigma mixer

sigma mixer mixing tank

mixing tank Ribbon blender

Ribbon blender kneading machine

kneading machine Reactors

Reactors High-Shear Mixers

High-Shear Mixers

CN

CN

HOME

HOME

Related Suggestion

Related Suggestion

Jul 25,2024

Jul 25,2024

Tel

Tel

Email

Email

Address

Address