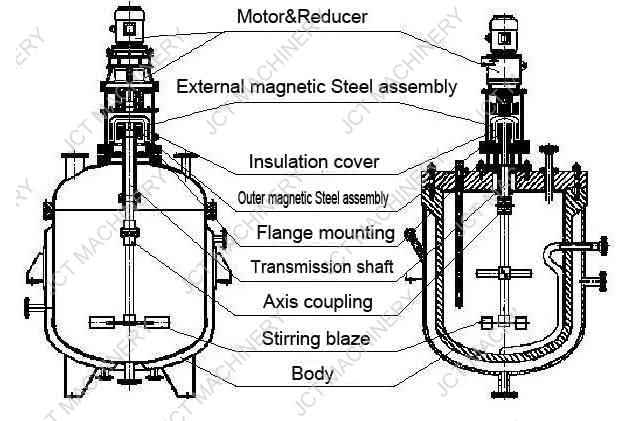

A. Simple Description of mixing tank:

1). Different capacity design from 50L to 50,000L.

2). Made of stainless steel mixing tank 304/ 316L, or other material (decide by client).

3). chemical reactor Have jacket and coil-pipe style.

4). Vacuum and high-pressure mixing tank are available.

5). Super mixer for most chemicals / food materials mixing tank and reacting.

6). Widely used in producing resins, adhesives, paints, cosmetics, pharmaceuticals and other chemical productions.

7). Can be heated by oil or water or steam, temperature range: 0 - 500 centigrade.

8). With different mixing paddles, can be designed as requirements.

9). Supply whole production line for different products, also including producing technology.

B: Sets of Equipment:

1. Unsaturated polyester resin, alkyd, polyester powder coating, curing agent and other

complete sets of production equipment

2.Complete sets of production equipment, such as acrylic resin, phenolic resin, epoxy resin,

3.Amino resin, polyurethane resin, PVC resin complete set of production equipment

4.Complete sets of production equipment, such as polyacrylic emulsion , white latex,

waterborne polyurethane, printing and dyeing auxiliaries

5.Silicone resin, silicone oil and other complete sets of production equipment

6.Complete equipment for production of hot melt adhesive

7. Solvent type PU rubber, chloroprene rubber, adhesive, PVC adhesive, urea formaldehyde

glue, such as complete sets of production equipment

8.Waste silica gel cracking, distillation, recovery of complete sets of production equipment

9. Paint, ink dispersion, mixing, mixing equipment:

The stirring blades of mixing tank:

How to select the appropriate mixing tank:

Take a example by the FYF-1000

FYF means the reactor kettle series(mainly for liquid, solvent making industry), 1000 means the design volume is 1000liters. The effect volume is about 80% of the tank, that means 800 liters/batch.

The daily production capacity depends on the reacting time.

Company introduction

1). Profession:

We have focused on this area for over 10 years, and the boss of JCT is a professional engineer who has 20 years’ experience in what we are concentrating on mixing tank:

2). Powerful team:

A 5-experienced-engineer designing team + a 35-skilled-technician team + a 10-passionate-sales team make up the JCT big team.

3). Achievement:

JCT was set up at 2004, through about 10 years’ endeavor, our products has been sold to most important industrial district in China, such as Guangdong, Shangdong, Jiangsu, Zhejiang, Fujian and so on. And we have edged ourselves into the top 5 in China.

From 2009, JCT started the international marketing. Now, we have set our feet in North America, Europe, South Aria, Africa etc.

1)Equipment volume: 20-50000L (volume in accordance with the requirements of the

design.)

2 ) Reaction temperature : -20℃~300℃。

3 ) Reaction pressure -0.1~1.6Mpa.

4 ) Equipment Material : SS304 , SS321 , SS316L stainless steel ; Q235-B carbon steel.

5 ) Mixing type: blade type, anchor type, frame type, screw belt type, turbine type,

dispersing disc type, combination type and so on.

6 ) Heating method: the heat conduction oil circulation heating, Electric heating in jacket,

steam heating, hot water heating.

7) Transfer structure: the outer jacket, the outer half tube, inner tube.

Product line

Product line sigma mixer

sigma mixer mixing tank

mixing tank Ribbon blender

Ribbon blender kneading machine

kneading machine Reactors

Reactors High-Shear Mixers

High-Shear Mixers

CN

CN

HOME

HOME

Related Suggestion

Related Suggestion

Jul 25,2024

Jul 25,2024

Tel

Tel

Email

Email

Address

Address