A. Equipment introduction of high pressure reactor:

1). Different capacity design from 50L to 50,000L.

2). Made of stainless steel mixing tank 304/ 316L, or other material (decide by client).

3). chemical reactor Have jacket and coil-pipe style.

4). Vacuum and high-pressure mixing tank are available.

5). Super mixer for most chemicals / food materials mixing tank and reacting.

6). Widely used in producing resins, adhesives, paints, cosmetics, pharmaceuticals and other chemical productions.

7). Can be heated by oil or water or steam, temperature range: 0 - 500 centigrade.

8). With different mixing paddles, can be designed as requirements.

9). Supply whole production line for different products, also including producing technology.

B. The Stirring blades of high pressure reactor

C. Applied range :

The reactor is widely used in resin, adhesives, inks, pesticides, chemical and other industries.

Q : How do I pay for my purchase order?

A: T/T or L/C.

Q:What’s the delivery time?

A:It will take about 30 days to finish an order,but the exact time is according to actual situation.

Q:How about the warranty control?

A:One year warranty for the equipment since sold.If quality problem occurs,please feel free to contact us.

Pre-sale service:

♦ We can supply you all the details you need.

♦ We can design the drawings according to your requirements.

♦ We can also customize the products according the requirement.

After-sale service:

♦ We provide long-term after-sale service.

♦We can help you to install in your factory If necessary,the technicians can go to debug the machine,but the air ticket,visa,accommodation and labor cost provided by your party.

♦ You can consult any relevant questions by phone,E-mail and communicate online.

How to select the appropriate machine:

Take a example by the FYF-1000

FYF means the reactor kettle series(mainly for liquid, solvent making industry), 1000 means the design volume is 1000 liters.The effect volume is about 80% of the tank, that means 800 liters/batch.

The daily production capacity depends on the reacting time.

JCT Machinery Co.,Ltd, your best choice!

The Hot sale high pressure reactor is widely used in resin, adhesives, inks, pesticides, chemical and other industries.

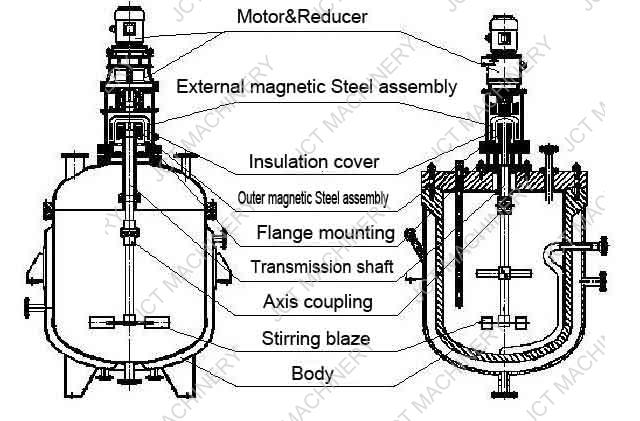

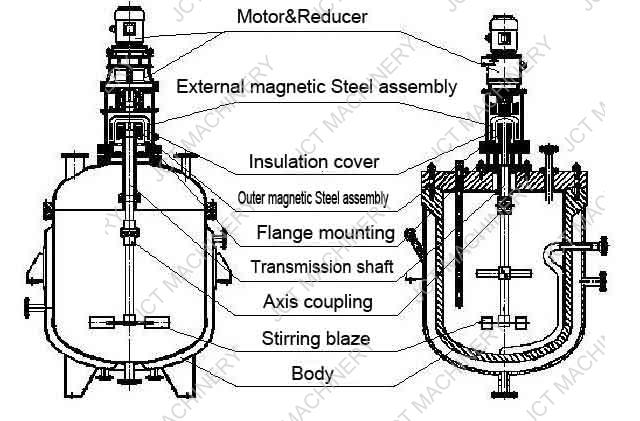

Shaft seal structure

The Technical Parameters of high pressure reactor:

1)Equipment volume: 20-50000L (volume in accordance with the requirements of the

design.)

2 ) Reaction temperature : -20℃~300℃。

3 ) Reaction pressure -0.1~1.6Mpa.

4 ) Equipment Material : SS304 , SS321 , SS316L stainless steel ; Q235-B carbon steel.

5 ) Mixing type: blade type, anchor type, frame type, screw belt type, turbine type,

dispersing disc type, combination type and so on.

6 ) Heating method: the heat conduction oil circulation heating, Electric heating in jacket,

steam heating, hot water heating.

7) Transfer structure: the outer jacket, the outer half tube, inner tube.

Contact information:

If you need to know the detailed equipment configuration, production technology, production

process, please contact us.

Email:[email protected]

Mobile: 0086-181 3837 3963(WhatsApp, Wechat)

Address: Donglian Jincheng Industrial Zone, Danzao Town, Nanhai, Foshan, Guangdong, China.

Product line

Product line sigma mixer

sigma mixer mixing tank

mixing tank Ribbon blender

Ribbon blender kneading machine

kneading machine Reactors

Reactors High-Shear Mixers

High-Shear Mixers

CN

CN

HOME

HOME

Related Suggestion

Related Suggestion

Jul 25,2024

Jul 25,2024

Tel

Tel

Email

Email

Address

Address