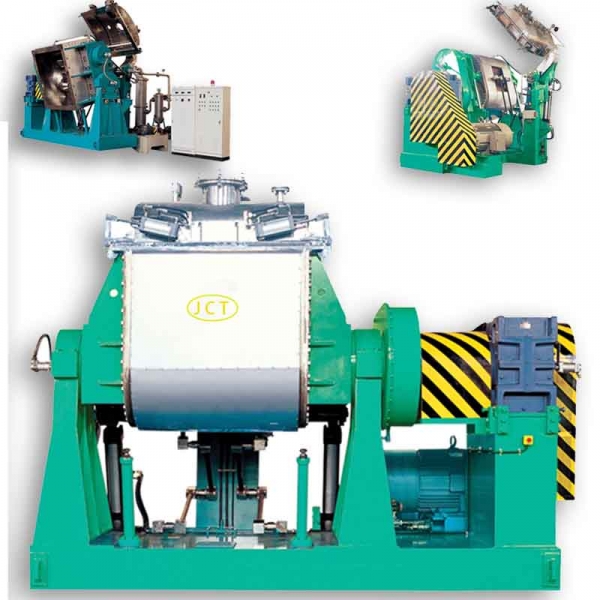

1)The Rubber kneader mixing machine is a high viscosity elastic plastic material mixing, kneading, broken and scattered, and the ideal equipment for the aggregation,with advantages of mixing and kneading high efficiency;

2)Mixing method: using two different speed propeller (Z type or ∑type) strong extrusion, shear, the materials are mixed uniformly.

3)Kneader can be divided into the vacuum type, pressure type, pressure type ;

4)Heating cooling method: heat conduction oil heating, jacket electric heating, steam heating,water cooling, etc.;

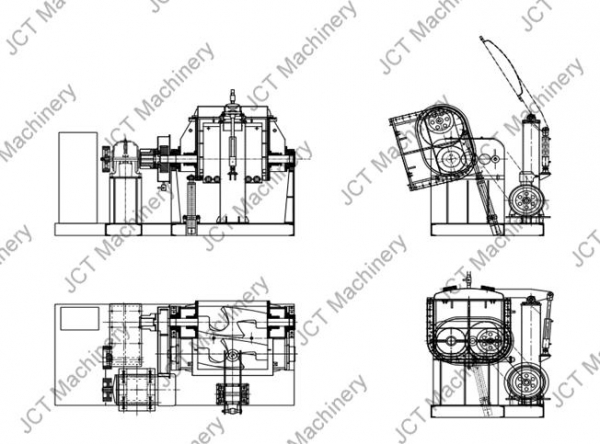

5)Open cover: hydraulic open cover.

6)Discharging mode: hydraulic dump cylinder dump, bottom discharging, screw extrusion, etc.

7)be installed on the device a variety of safety, measurement, control and instrumentation.

8)The parts contact with material are made of stainless steel material, can also be in accordance with the requirements of the buyer;

9)the shaft seal is sealed with vacuum structure. To prevent the sealing filler particles into the cylinder,it can ensure the quality and purity of the material.

200L Rubber kneader mixing machine

300L Rubber kneader mixing machine

500L Rubber kneader mixing machine

1000L Rubber kneader mixing machine

2000L Rubber kneader mixing machine

Welcome to learn more details from JCT Machinery!

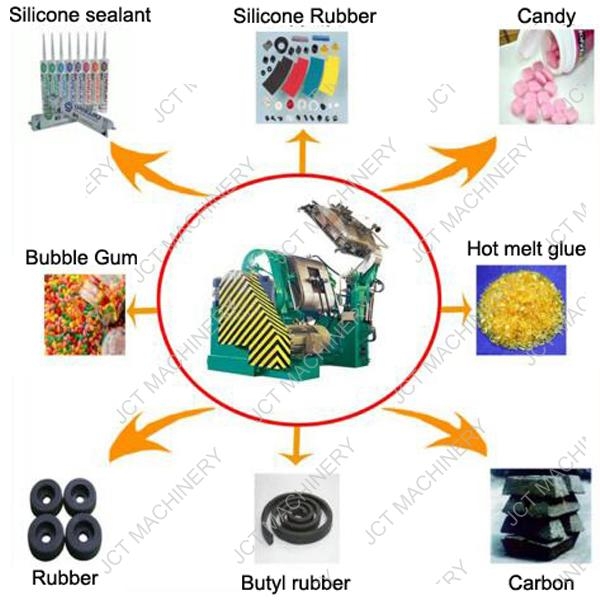

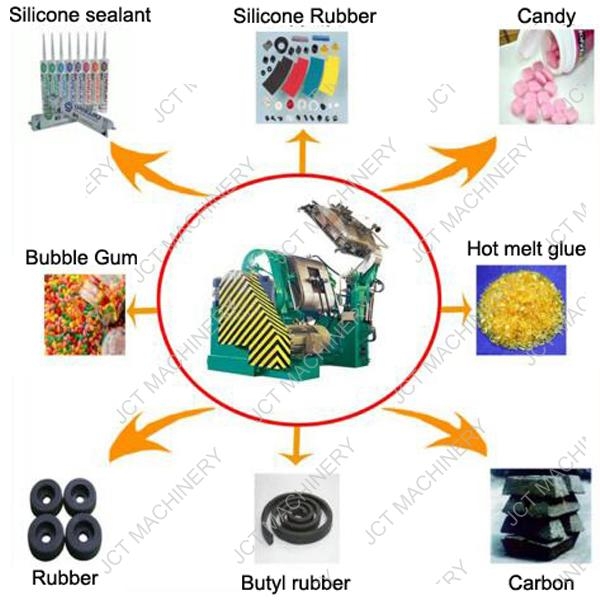

Rubber kneader mixing machine is widely used in high viscosity sealant, silicone rubber, adhesive, BMC, CMC, ink, pigment, dyes, medicine, resin, plastic, rubber, cosmetics and other industries.

|

Model

|

Cylinder

volume

|

KW

Motor

power

|

Discharging mode

|

Heating mode

|

Remarks

|

|

total volume

|

Feeding quantity

|

|

NHZ-5

|

5

|

3

|

1.5

|

Hydraulic cylinder

|

1)Circular heating

2)Electric heating

in jacket

3) Steam heating

|

Motor power can be modified according to actual requirement

|

|

NHZ-50

|

50

|

30

|

5.5

|

|

NHZ-100

|

100

|

60

|

11

|

|

NHZ-200

|

200

|

120

|

15

|

1)Hydraulic cylinder

2)bottom discharge

3) Screw feeding

|

|

NHZ-300

|

300

|

180

|

22

|

|

NHZ-500

|

500

|

300

|

37

|

|

NHZ-1000

|

1000

|

600

|

45

|

|

NHZ-2000

|

2000

|

1200

|

75

|

|

NHZ-3000

|

3000

|

1800

|

90

|

|

NHZ-5000

|

5000

|

3000

|

132

|

|

Statement:

1. Working temperature: -10~300℃;

2. Working pressure: cylinder body: -0.1-0.2MPa, clip sleeve: 0-0.6MPa

3. Stirring speed: fast paddle 0-48rpm, slow paddle 0-32rpm

|

Contact information:

If you need to know the detailed equipment configuration, production technology, production

process, please contact us.

Email:[email protected]

Mobile: 0086-181 3837 3963(WhatsApp, Wechat)

Address: Donglian Jincheng Industrial Zone, Danzao Town, Nanhai, Foshan, Guangdong, China.

Product line

Product line sigma mixer

sigma mixer mixing tank

mixing tank Ribbon blender

Ribbon blender kneading machine

kneading machine Reactors

Reactors High-Shear Mixers

High-Shear Mixers

CN

CN

HOME

HOME

Related Suggestion

Related Suggestion

Jul 25,2024

Jul 25,2024

Tel

Tel

Email

Email

Address

Address