Jīnchǎngtài: revealing the production process of mixing rubber

With the increasing use of rubber compounds, rubber compounds are becoming more and more well-known. There are not many people who have invested in the production of rubber compounds. This involves the production of rubber compounds. Jinhaotai Machinery has many years of experience in the production of rubber mixing equipment. Now we will inform you about the production process of rubber mixing.

The basic preparation process of compounded silicone rubber The compounded silicone rubber can be generally prepared on a general-purpose rubber mixer, and the large-scale production is carried out in a kneader or a closed mixing machine.

1. First, if you want to put the silicone rubber into the production, you must add the vulcanizing agent before you can vulcanize it on the vacuum vulcanizer. There are two kinds of vulcanization methods: 50 kg or less of compounded silicone rubber and sulfur can be added to the mill to a certain proportion of the vulcanizing agent, and the mixture is smooth until the surface is smooth; 50 kg or more of the kneaded silicone rubber must be added to the kneading machine. The vulcanizing agent is added until the kneading is uniform and then kneaded on the mill roll until the surface is smooth.

2. The vulcanized silicone rubber with the vulcanizing agent can be directly put into production. Firstly, the oil paper for packaging and mixing the silicone rubber should be opened, and the raw material of the kneaded silicone rubber should be cut into pieces by a blade and then put into a vacuum vulcanizer. Into the rubber compound, it is necessary to weigh the weight on the electronic scale, and then place the rubber evenly on the mold. The amount of compounded silicone rubber compound needs to be based on the weight and size of the silicone product itself.

3. Finally, the vulcanization temperature and time should be adjusted. Generally, the vulcanization temperature of the silica gel product is between 170 ° C and 180 ° C, and the vulcanizing agent time is 60 s - 180 s. The specific quality is based on the product quality. After repeated adjustment tests and selection of the best vulcanization temperature and time, a brand new silicone product was officially released.

Production of HTV compounding rubber Jinyitai recommended that you use vacuum kneading machine, Guangdong Jinhaotai Machinery can provide you with a complete set of equipment for the production of HTV rubber compound, welcome new and old customers to call us for consultation.

Jin Chang Tai Chemical Machinery Co.,Ltd.

Technical parameters of Hot melt sealant machinery:

|

Specifications |

Effective volume (L) |

Heating |

Heating(colding) structure |

Impeller structure |

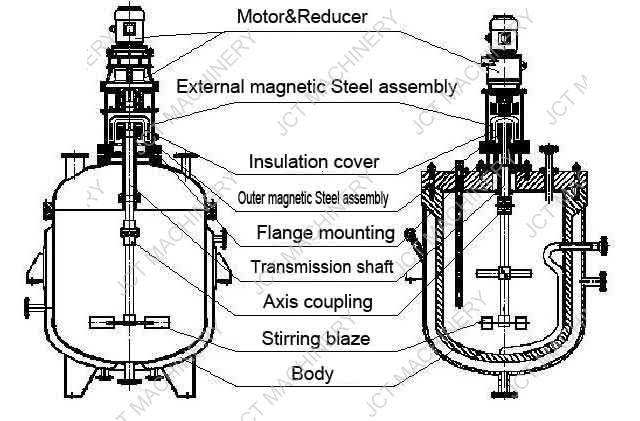

Shaft seals |

Material within the cylinder |

Remarks

|

|

FYF-50L |

50 |

HTF

|

Jacket

|

Oblique paddle

|

Single mechanical seal

|

304 321 316 Q235 |

1, the motor power size, stirring speed level determined according to actual requirements.

|

|

FYF-100L |

100 |

||||||

|

FYF-200L |

200 |

||||||

|

FYF-300L |

300 |

||||||

|

FYF-500L |

500 |

||||||

|

FYF-1000L |

1000 |

||||||

|

FYF-1500L |

1500 |

||||||

|

FYF-2000L |

2000 |

||||||

|

FYF-2500L |

2500 |

||||||

|

FYF-3000L |

3000 |

||||||

|

FYF-4000L |

4000 |

||||||

|

FYF-5000L |

5000 |

||||||

|

FYF-6000L |

6000 |

||||||

|

FYF-8000L |

8000 |

||||||

|

FYF-10000L |

10000 |

||||||

|

FYF-12000L |

12000 |

||||||

|

FYF-16000L |

16000 |

||||||

|

FYF-20000L |

20000 |

||||||

|

FYF-25000L |

25000 |

||||||

|

FYF-30000L |

300000 |

Contact information:

If you need to know the detailed equipment configuration, production technology, production

process, please contact us.

Email:[email protected]

Mobile: 0086-181 3837 3963(WhatsApp, Wechat)

Address: Donglian Jincheng Industrial Zone, Danzao Town, Nanhai, Foshan, Guangdong, China.

Please feel free to contact us by email or the form below, we will soon reply within 24 hours.

Related Suggestion

Related Suggestion

Jul 22,2024

Jul 22,2024

Tel

Tel

Email

Email

Address

Address

Donglian Jincheng Industrial Zone, Danzao Town, Nanhai District, Foshan City, Guangdong Province, China

HOME

HOME