The introduction of mixing tank:

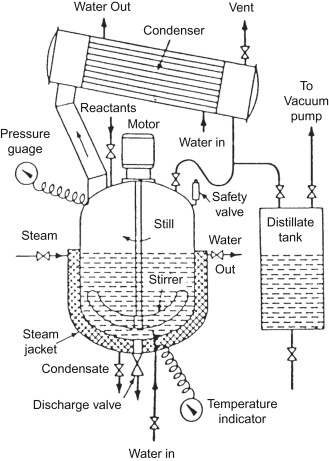

Mixing tank is the main chemical reaction of the typical production equipment, which is widely used in resins, adhesives, paint, cosmetics, pharmaceutical and other chemical production. To break down or combined the materials through mixing, filling and cooling, to promote the reaction of polymerization. The mixing tank consists of body, gears, mixing devices, heating devices, cooling devices, seal composition and some corresponding auxiliary equipment: distillation column, condenser, water separator, collecting cans, filters etc.

The stirring blades of mixing tank:

Sets of Equipment in mixing tank:

1. Unsaturated polyester resin, alkyd, polyester powder coating, curing agent and other

complete sets of production equipment

2.Complete sets of production equipment, such as acrylic resin, phenolic resin, epoxy resin,

3.Amino resin, polyurethane resin, PVC resin complete set of production equipment

4.Complete sets of production equipment, such as polyacrylic emulsion , white latex,

waterborne polyurethane, printing and dyeing auxiliaries

5.Silicone resin, silicone oil and other complete sets of production equipment

6.Complete equipment for production of hot melt adhesive

7. Solvent type PU rubber, chloroprene rubber, adhesive, PVC adhesive, urea formaldehyde

glue, such as complete sets of production equipment

8.Waste silica gel cracking, distillation, recovery of complete sets of production equipment

9. Paint, ink dispersion, mixing, mixing equipment

1). Profession:

We have focused on this area for over 10 years, and the boss of JCT is a professional engineer who has 20 years’ experience in what we are concentrating on!

2). Powerful team:

A 5-experienced-engineer designing team + a 35-skilled-technician team + a 10-passionate-sales team make up the JCT big team.

3). Achievement:

JCT was set up at 2004, through about 10 years’ endeavor, our products has been sold to most important industrial district in China, such as

Guangdong, Shangdong, Jiangsu, Zhejiang, Fujian and so on. And we have edged ourselves into the top 5 in China.

From 2009, JCT started the international marketing. Now, we have set our feet in North America, Europe, South Aria, Africa etc.

Our credo--"Quality and Service first; Profit second !!"

Our Mission--"To Serve you better , to try our best to achieve a win--win situation with you !!!

Pre-sale services:

♦ We can supply you all the details you need.

♦ We can design the drawings according to your requirements.

♦ We can also customize the products according the requirement.

After-sale service:

♦ We provide long-term after-sale service.

♦We can help you to install in your factory If necessary,the technicians can go to debug the machine,but the air ticket,visa,accommodation and labor cost provided by your party.

♦ You can consult any relevant questions by phone,E-mail and communicate online.

Q:How do I pay for my purchase order?

A: T/T or L/C.

Q:What’s the delivery time?

A:It will take about 30 days to finish an order,but the exact time is according to actual situation.

Q:How about the warranty control?

A:One year warranty for the equipment since sold.If quality problem occurs,please feel free to contact us.

About JCT Machinery Co.,Ltd

1). The company build in 2006, now there are about 50 people work for it.

2). Our credo is: JCT —— your truthful partner in China.

We are strive to become the leader in this industry and produce the world-class mixing equipment.

3). Our products including reactor, kneader, planetary mixer, power mixer etc, and can be used for resins, adhesives, paint, sealants and powder mixing etc.

4). Our products have exported to Ethiopia, Saudi Arabia, Japan, India, Russia, Sudan, Italy etc.

JCT Machinery Co.,Ltd, you best choice!

1)Equipment volume: 20-50000L (volume in accordance with the requirements of the design.

2 ) Reaction temperature : -20℃~300℃。Stainless Steel Chemical Reactor Stainless Steel Chemical Reactor

3 ) Reaction pressure -0.1~1.6Mpa.

4 ) Equipment Material : SS304 , SS321 , SS316L stainless steel ; Q235-B carbon steel.

5 ) Mixing type: blade type, anchor type, frame type, screw belt type, turbine type,

dispersing disc type, combination type and so on.

6 ) Heating method: the heat conduction oil circulation heating, Electric heating in jacket,

steam heating, hot water heating.

7 ) Transfer structure: the outer jacket, the outer half tube, inner tube

Product line

Product line sigma mixer

sigma mixer mixing tank

mixing tank Ribbon blender

Ribbon blender kneading machine

kneading machine Reactors

Reactors High-Shear Mixers

High-Shear Mixers

CN

CN

HOME

HOME

Related Suggestion

Related Suggestion

Jul 25,2024

Jul 25,2024

Tel

Tel

Email

Email

Address

Address