Why Choose Grease Production Line Turnkey Project? | JCT Machinery

Feb 11,2025

Feb 11,2025

JCT

JCT

Application Fields of Grease

1. Automobile Industry

It is used for lubrication of automobile engines, chassis, steering systems, wheel bearings and other parts, and has anti-wear, anti-corrosion and high temperature resistance.

2. Industrial Machinery

Grease is used in various industrial equipment, such as machine tools, rolling bearings, gears, transmission systems, etc., to reduce friction and extend the life of equipment.

3. Household Appliances

Grease is used in the moving parts of household appliances, such as washing machines, power tools, fans, etc., to reduce noise and increase durability.

4. Aerospace and Military

In spacecraft and military equipment, grease has the functions of anti-corrosion, high temperature and high pressure resistance.

5. Food Industry

Grease used in the food industry needs to meet food grade standards and is widely used in the lubrication of food processing equipment.

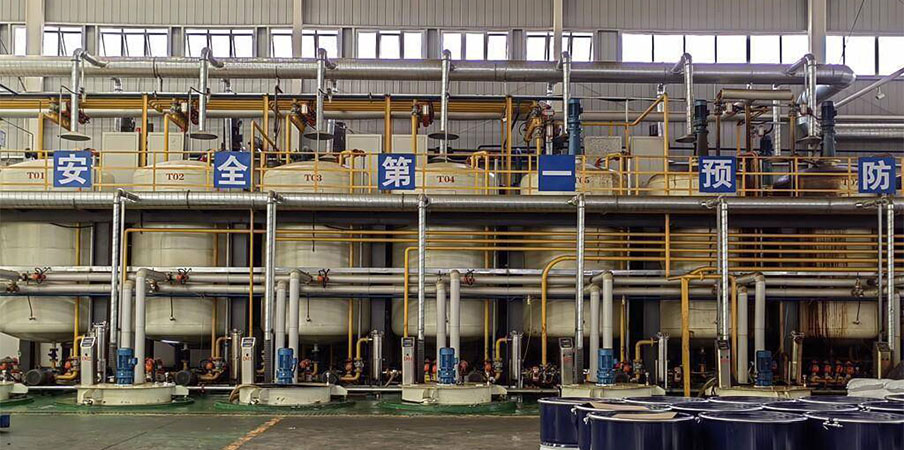

Main Equipments of Grease Production Line

1. Reactor

- Function: Reactor is mainly used to mix base oil, thickener and additives. Through heating, stirring and other methods, the thickener is fully dissolved in the base oil to form a uniform viscous substance.

- Features: Usually a jacketed reactor is used, and the temperature can be controlled by the jacket. It has a stirring system to ensure uniform mixing of materials.

2. Vacuum Degasser

- Function: Used to remove bubbles and air impurities generated during the production of grease to prevent bubbles from affecting the quality of grease.

- Features: Through vacuum degassing, foam can be effectively reduced to ensure the density and stability of the grease.

3. Cooling System

- Function: Grease is prone to excessively high temperatures during the heating process. The cooling system helps to quickly reduce the temperature after the product is completed, so that the grease solidifies and forms.

- Features: Usually equipped with a water cooling system or an air cooling system to ensure temperature control accuracy.

4. Filtration System

- Function: Remove impurities, undissolved substances or particles during the production of grease to ensure the purity and quality of the final product.

- Features: Through pressure filtration or vacuum filtration, the high purity of grease can be ensured.

Advantages of Grease Production Line

- Efficient Production: Grease production line can be automated, which can improve production efficiency and reduce manual operations.

- Accurate Proportioning: Fully automated system ensures the precise proportioning of raw materials and improves product consistency and quality.

- Environmental Protection: Grease production process can adjust the proportion of additives according to demand to reduce the negative impact on the environment.

- Customization: It can produce different types of grease according to customer needs to meet the use needs of various mechanical equipment.

CN

CN

HOME

HOME About Hot Melt Adhesive Film Production Line | JCT Machinery

About Hot Melt Adhesive Film Production Line | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address