What Is Enamel Reactor? | JCT Machinery

Dec 16,2023

Dec 16,2023

JCT

JCT

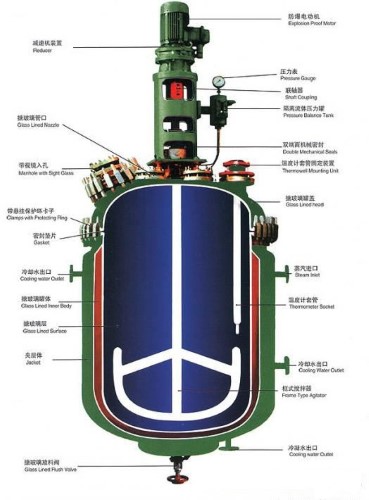

What is enamel reactor?

Enamel reactor is made by lining the inner surface of a steel container with high-silica-containing glass, which is burned at high temperature and firmly adhere to the metal surface to become a composite product. Therefore, it has the dual advantages of the stability of glass and the strength of metal, and is an excellent corrosion-resistant equipment.

What are the characteristics of enamel reactor?

1. Corrosion Resistance

Enamel coating has excellent corrosion resistance and can resist the erosion of acids, alkalis and other chemical substances, and is suitable for handling the reactions of corrosive substances.

2. High Temperature Resistance

Enamel reactor can withstand relatively high temperatures and is suitable for processes that require heating reactions.

3. Hygiene

Enamel coating has a smooth surface, is easy to clean and complies with hygienic standards, making it suitable for applications in the pharmaceutical and food industries that require a high level of hygiene.

4. Anti-wear

Enamel coatings have good anti-wear properties and are able to maintain the integrity of the coating during stirring and reaction processes.

5. Smooth and Easy To Clean

The surface of enamel reactor is smooth, difficult to adhere to substances, easy to clean, and helps maintain the hygiene of the production environment.

6. Pressure Resistance

Enamel reactor usually has good pressure resistance and can withstand a certain internal pressure.

7. Chemical Stability

Enamel coating has good stability to many chemicals and is not easily affected by chemical reactions.

8. Versatility

Different types of stirrers, heating / cooling systems and other accessories can be configured according to different reaction needs, making it versatile.

9. Mass production

Enamel reactor can be used for mass production and is suitable for large-scale industrial production processes.

10. Safety

The design of enamel reactor usually takes safety factors into account, including appropriate safety valves, sensors and control systems to ensure the safe operation of the reaction process.

CN

CN

HOME

HOME Characteristics Of Ribbon Blender | JCT Machinery

Characteristics Of Ribbon Blender | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address