Ribbon Blender Drawing | JCT Machinery

Dec 18,2023

Dec 18,2023

JCT

JCT

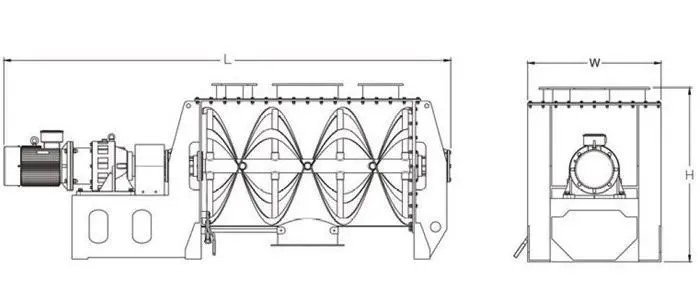

Ribbon blender is a type of industrial blender commonly used for the mixing of dry powders, granules and other solid materials. It consists of a horizontal, U-shaped through or container with a ribbon-like agitator that rotates on two shafts inside the trough. Ribbon agitator design facilitates the gentle and efficient blending of materials.

Ribbon Blender Structure

1. Trough or Container

Main body of the ribbon blender is the U-shaped trough or container. It procides a chamber for holdinig the materials to be mixed. The trough is often made of stainless steel for durability and easy cleaning.

2. Ribbon Agitator

Ribbon agitator is the central mixing element of ribbon blender. It consists of two helical blades that are welded to and spiraled around the agitator shafts. The ribbon design promotes a well-balanced mixing action, ensuring that materials are moved both radially and laterally within the trough.

3. Agiitator Shafts

There are typically twom agitator shafts positioned parallel to each other along the length of the trough. These shafts support and drive the ribbon agitator. The shafts are often supported by bearings and extend beyond the ends of the trough for connection to the drive system.

4. End Plates

The ends of the trough are closed by en plates that secure the agitator shafts in place. The end plates help contain the materials within the mixing chamber during operation.

5. Drive System

The drive system powers the agitator shafts, causing the ribbon agitator to rotate. The drive system is typically located at one end of the blender and may concist of an electric motor, gearbox and other components. Variable speed drives may be used to control the mixing speed.

6. Discharge Valve

A discharge valve is located at the bottom of the trough to facilitate the removal of the mixed materials from the blender. The valve can be manually operated or pneumatically controlled.

7. Lid or Cover

Ribbon blender may has a lid or cover that provides access to the mixing chamber. The lid is designed for easy opening and closing, allowing operators to add or remove materials conveniently.

8. Support Legs

Ribbon blenders are typically mounted on support legs to elevate the mixinig chamber above the ground. This provides clearance for the discharge valve and facilitates cleaning and maintenance underneath the ribbon blender.

9. Safety Features

Some ribbon blenders are equipped with safety features such as interlocks, emergency stop buttons, and guarding to ensure safe operation.

CN

CN

HOME

HOME What Is PU Glue? | JCT Machinery

What Is PU Glue? | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address