Reactor: Type Of Stirrer And Uses

Nov 08,2023

Nov 08,2023

JCT

JCT

Reactors are vessels used in various chemical and industrial processes to carry out chemical reactions, mix, and process materials.

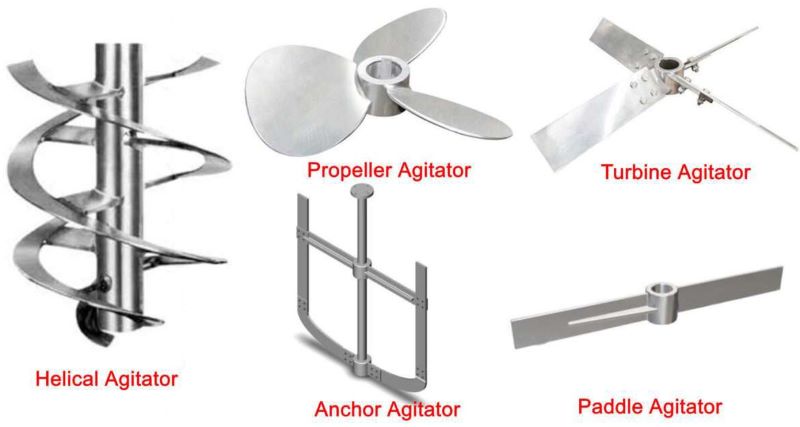

Stirrers, or agitators, play a crucial role in these reactors by providing mixing, dispersion, and agitation of the reactants and materials. What type of stirrer we choose depends on the specific requirements of the reaction and the properties of the materials being processed.

Different type of stirrer has different effect

• Anchor or Paddle Stirrer: Anchor stirrers are used for low to medium-viscosity materials. They have a wide, flat blade that provides good radial and axial flow. Common applications include blending, dissolution, and heat transfer processes.

• Turbine Stirrer: It is commonly used in mixing and aeration applications. They are efficient for blending and maintaining uniform suspension in low-viscosity liquids.

• Helical Stirrer: It has a ribbon-like design and are used for mixing high-viscosity materials, pastes, and non-Newtonian fluids. They provide good axial flow and are effective for heat transfer.

• Propeller stirrer: It is used in industrial and laboratory reactors for mixing, blending, and agitating liquid and solid-liquid materials. Propeller stirrers are known for their efficiency in providing axial flow.

Reactor is a container or device used for chemical reactions, mixing, stirring, and processing of various materials. It plays an important role in many different industrial and laboratory processes.

The main functions of Reactor include:

1. Chemical reaction

2. Mix and stir

3. Dissolve and mix

4. Heating and cooling

5. Storage and transmission

6. Control reaction conditions

7. Chemical engineering

8. Pharmaceutical manufacturing

CN

CN

HOME

HOME What Is Kneader?

What Is Kneader?  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address