Paint Reactor | JCT Machinery

Apr 09,2024

Apr 09,2024

JCT

JCT

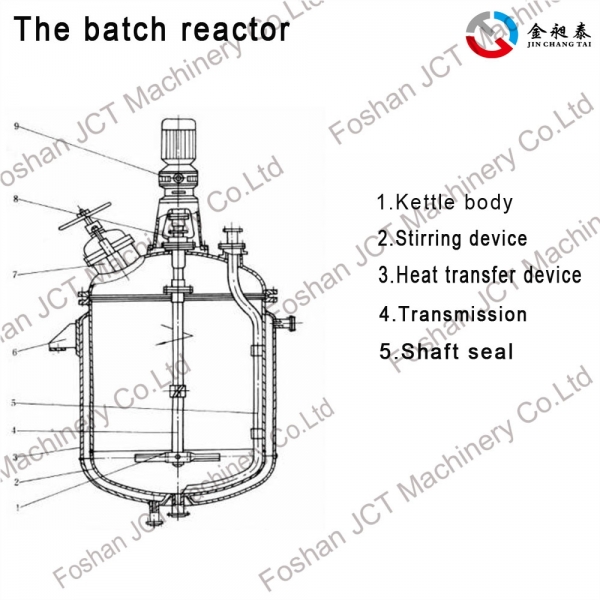

Paint reactor in paint production line is important equipment used to prepare paints, coatings and related products. It plays the functions of mixing, reaction, heating or cooling in the production line. Here are some key features and uses of paint reactor:

1. Mixing and Reaction

Paint reactor is used to mix raw materials, solvents, pigments and additives together ro promote chemical reactions (such as polymerization or cross-linking) or physical mixing to prepare the required paint or coating formulation.

2. Heating or Cooling

Paint reactor is usually equipped with a heating or cooling system, which can heat or cool the reaction system as needed to control the reaction rate or improve the performance of the product.

3. Sealing Performance

Since it involves the mixing and reactioin of liquids and gases, paint reactor usually need to has good sealing properties to prevent material leakage or external impurities from entering the reaction system.

4. Stirring Mechanism

Paint reactor is usually equippeds with a stirring mechanism to mix the reaction materials to ensure uniform reaction and prevent the materials from solidifying or agglomerating.

5. Material Selection

The interior of paint reactor is usually made of corrosion-resistant materials (such as stainless steel) to adapt to different types of raw materials and reaction conditions and to ensure long-term stable operation of the equipment.

6. Automated Control

Some advanced paint production lines may be equipped with automated control systems that can monitor the reaction process, record data, and adjust parameters to improve production efficiency and product quality.

CN

CN

HOME

HOME Epoxy Glue Production Line | JCT Machinery

Epoxy Glue Production Line | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address