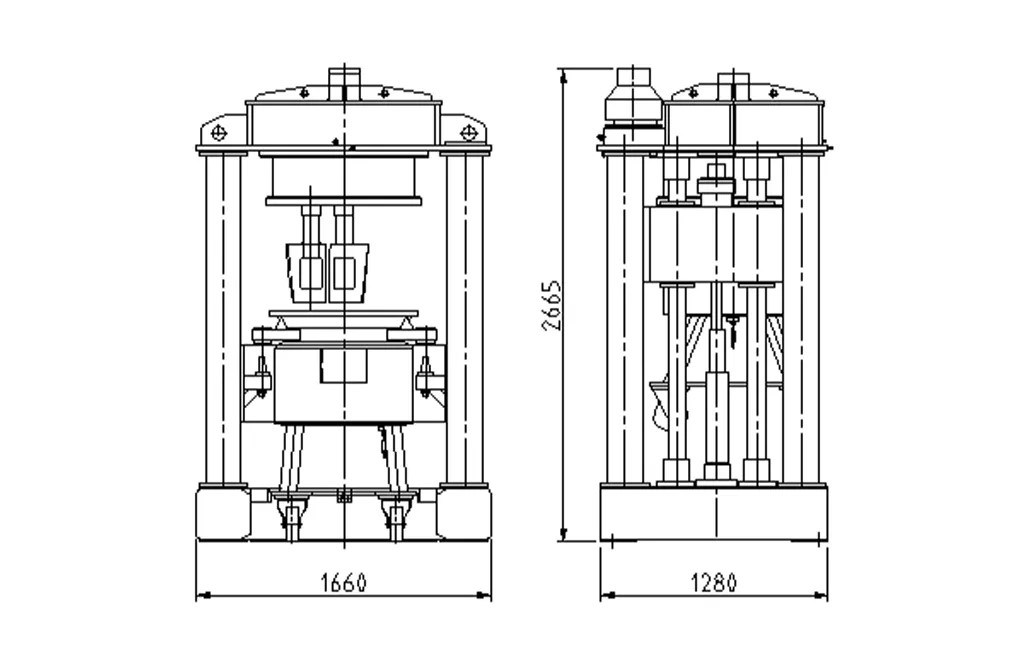

Key components of JCT Vertical Kneader

Oct 17,2023

Oct 17,2023

JCT

JCT

• Mixing Chamber: The mixing chamber is the core part of the vertical kneader, usually in a cylindrical or conical shape. This is the main area of the vertical kneader where materials are mixed, kneaded and stirred. The capacity of the mixing chamber can vary according to different applications and production needs.

• Agitator: Vertical kneaders usually contain an agitator, which can be spiral or blade-shaped. The mixer mixes materials together and achieves mixing and kneading through actions such as stirring, folding and compression.

• Motor: The motor is used to drive the mixer and provide rotational power. The motor is usually located on the top of a vertical kneader and is connected to the agitator through a mechanical connection part.

• Jacket: Some vertical kneaders have a jacket design that allows the temperature of the mixture to be controlled by external heating or cooling. This is important for materials that require temperature control when mixing.

• Feed and Discharge Ports: Vertical kneaders are usually equipped with one or more feed ports for adding raw materials and ingredients, and also have discharge ports for discharging the mixture.

• Control System: The vertical kneader control system usually includes buttons, switches and digital displays, which are used to set and monitor mixing time, speed, temperature and other parameters.

These components work together to enable the vertical kneader to effectively mix and knead high-viscosity materials to meet the production needs of different industries.

CN

CN

HOME

HOME Precautions For Using Vertical Kneader

Precautions For Using Vertical Kneader  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address