Internal Mixer And Sigma Mixer | JCT Machinery

May 10,2024

May 10,2024

JCT

JCT

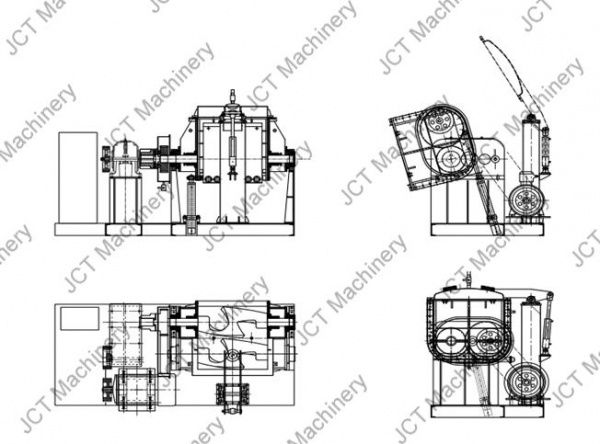

Internal Mixer

1. Efficient Mixing

The drum mixing principle of internal mixer can achieve efficient mixing and dispersion in a short time, and is suitable for some hot melt glue formulas that do not require strong shearing.

2. Fast Processing Speed

Due to the drum mixing, internal mixer usually has a fast processing speed, which helps to improve production efficiency.

3. Automated Control

Modern internal mixers are usually equipped with automated control systems, which make the operation relatively simple and reduce the difficulty of operation.

Sigma Mixer

1. Wide Range of Applications

Sigma mixer is suitable for mixing and processing a variety of materials, including hot melt glue. Especially suitable for materials requiring strong shear force and dispersion effect.

2. High Viscosity Materials

If the raw material of hot melt glue has a higher viscositym sigma mixer can cut and mix more efficiently, thereby improving uniformity.

3. Process Flexibility

Sigma mixer can usually adapt to different product requirements by adjusting mixing parameters, giving them greater process flexibility.

When selecting production equipment, we need to consider the following factors:

- Production Scale : if the production scale is larger, sigma mixer may be more suitable as its processing capacity is usually higher.

- Material Properties : consider the viscosity and other properties of hot melt glue to select more suitable equipment for processing.

- Product Requirements : if the product has high requirements for mixing uniformity, sigma mixer may be more suitable.

CN

CN

HOME

HOME What Is Phenolic Resin? | JCT Machinery

What Is Phenolic Resin? | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address