Alkyd Resin Production Line | JCT Machinery

Sep 26,2024

Sep 26,2024

JCT

JCT

What Is Alkyd Resin?

Alkyd resin is a synthetic resin produced by the reaction of polyols and polyacids, and is a thermosetting resin. It is mainly used in coatings, adhesives, printing inks, composite materials and other fields.

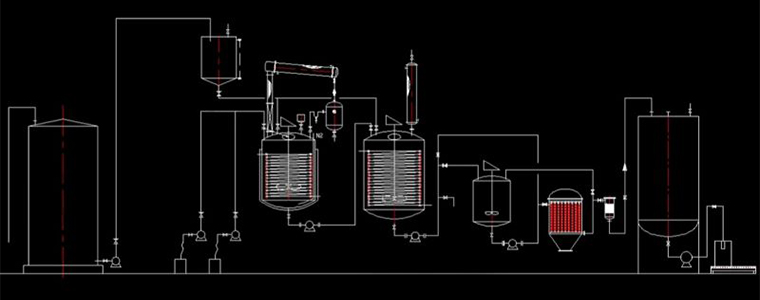

Alkyd Resin Production Line Equipment Configuration

- Raw material storage tank

- Metering tank

- Polymerizing reactor

- Fractionating column

- Vertical condenser

- Horizontal condenser

- Oil-water separator

- Dilute reactor

- Finished product storage tank

- Net plate filter

- Resin filling machine

- Heating and Cooling equipment

- Vacuum equipment

- Nitrogen generator

- Material conveying equipment

Capacity of Alkyd Resin Production Line

- 500kg/batch

- 1000kg/batch

- 2000kg/batch

- 3000kg/batch

- ... ...

- 30000kg/batch

Can be designed according to the capacity of the purchaser.

Alkyd Resin Production Process

1. Raw Material Preparation

Prepare the required raw materials according to the formula, including fatty acids, alcohols and other additives.

2. Batching and Mixing

Accurately weigh each component in the batching system and send it to the reactor for mixing.

3. Polymerization Reaction

Send the mixture into the reactor, heat and stir, control the temperature and time, and promote the polymerization reaction of alkyd resin.

4. Cooling and Filtration

After the reaction is completed, use the cooling system to reduce the temperature and remove insoluble matter by filtration.

5. Quality Inspection

Perform quality inspection regularly during the production process to ensure that the product meets technical standards.

6. Molding and Packaging

Alkyd resin is molded or coated and finally packaged.

CN

CN

HOME

HOME Flange Gasket For Reactor | JCT Machinery

Flange Gasket For Reactor | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address