Alkyd Resin And Acrylic Resin | JCT Machinery

Oct 22,2024

Oct 22,2024

JCT

JCT

1. Chemical Structure

- Alkyd Resin: Synthesized by esterification reaction of vegetable oil or fatty acid with polyol (such as glycerol), it is a kind of polyester resin, usually a thermosetting resin.

- Acrylic Resin: Mainly polymerized by acrylic acid and its ester (such as methyl methacrylate), it is a thermoplastic resin with high transparency and gloss.

2. Performance

- Alkyd Resin: It has good flexibility and weather resistance, suitable for coatings and paints, but poor water resistance and chemical resistance.

- Acrylic Resin: It has high transparency, good weather resistance, excellent chemical resistance and UV resistance, suitable for coatings that require high gloss and strong durability.

3. Curing Method

- Alkyd Resin: Usually oxidative curing is adopted, which releases water during the reaction and relies on oxygen in the air for curing.

- Acrylic Resin: It can be cured by various methods such as thermal curing, light curing (UV curing) or chemical curing, with fast curing speed and strong adaptability.

4. Application

- Alkyd Resin: It is mainly used in the production of paints, coatings, adhesives and other coatings, and is widely used in the construction, furniture and automotive industries.

- Acrylic Resin: It is commonly used in the poduction of high-performance coatings, transparent plastics, optical materials and protective coatings, and is suitable for automotive, electronics, furniture and other fields.

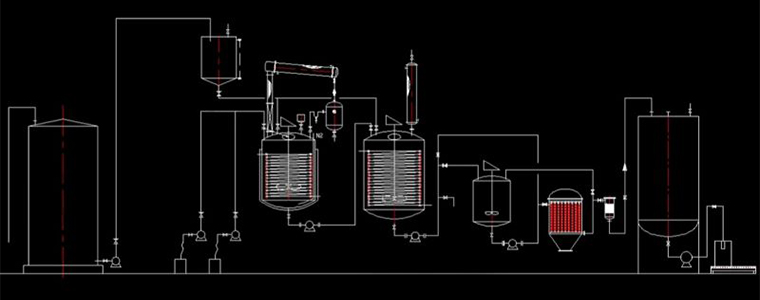

Differences In Production Line Equipment

1. Reactor

- Alkyd Resin: Reactor needs to be equipped with a dehydration device (such as a condensing reflux tower) to remove the water generated during the esterification process, and usually requires high temperature and corrosion resistant materials.

- Acrylic Resin: Reactor mostly uses polymerization reactions, usually requires strict temperature and pressure control, may be equipped with a high shear agitatpr and a cooling system, suitable for rapid reaction.

2. Grinding Equipment

- Alkyd Resin: Sand mills or bead mills are used for further grinding to ensure the fineness and uniformity of the final product.

- Acrylic Resin: Usually requires higher dispersion, and may use finer grinding equipment to achieve the desired transparency and gloss.

3. Curing and Drying Equipment

- Alkyd Resin: Curing mainly depends on the oxidation process, and drying equipment is usually used to accelerate curing.

- Acrylic Resin: UV curing equipment or thermal curing equipment may be required to meet the needs of rapid curing.

CN

CN

HOME

HOME Electric Heating Reactor Or Thermal Oil Heating Reactor | JCT Machinery

Electric Heating Reactor Or Thermal Oil Heating Reactor | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address