Three main points for maintenance of horizontal ribbon mixer

Aug 07,2020

Aug 07,2020

JCT

JCT

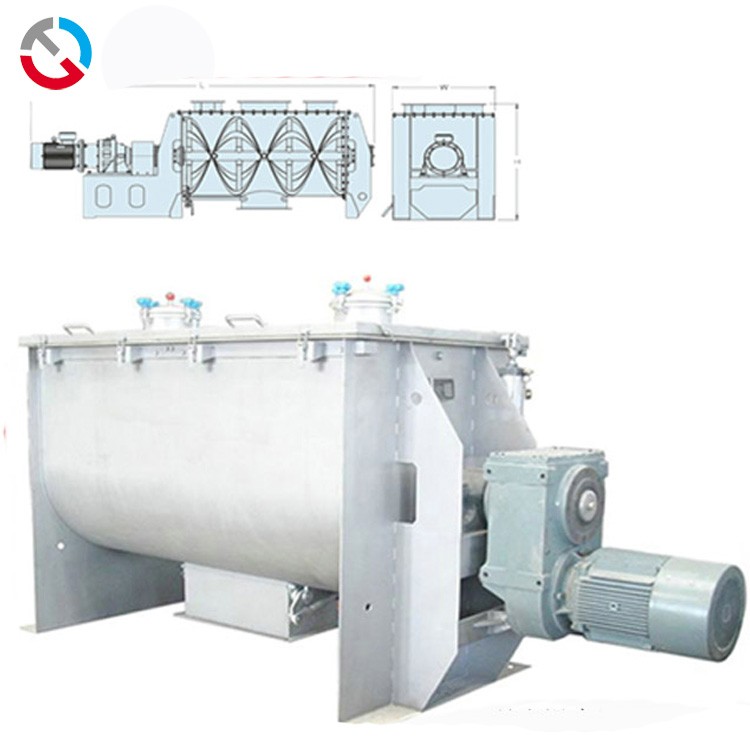

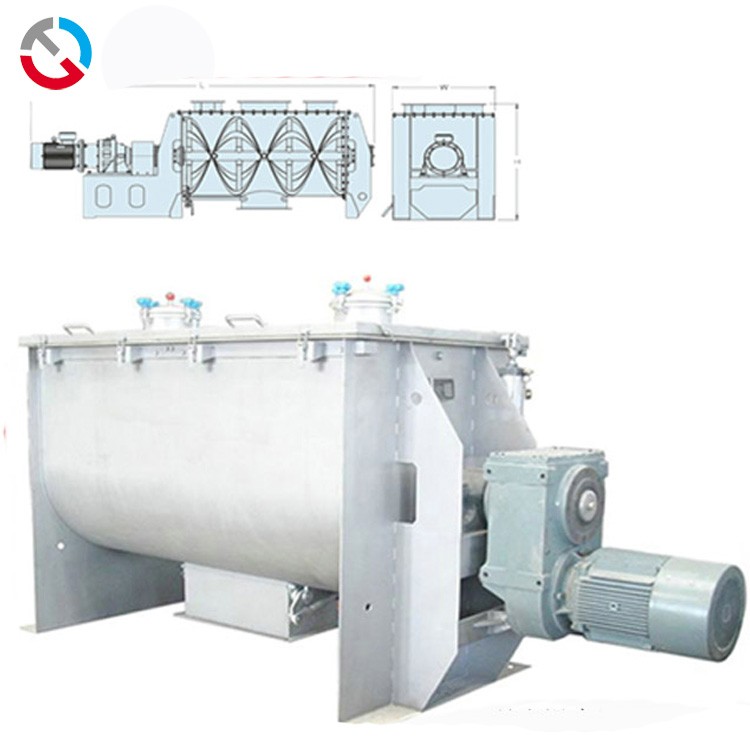

1. Equipment construction

The spiral belt mixer is usually used for the mixing of viscous or agglomerated powder particles, and the mixing of powder particles with liquid and pasty materials. At the same time, because the viscous material is not easy to clean, it is suitable for large-scale production, and various mixing occasions are not frequently changed. In two or three layers, the outer screw converges the material from both sides to the center, and the inner screw convections the material from both sides of the center to form convective mixing.

2. Working principle

The drive shaft of the mixer is provided with double spiral blades. The inner screw conveys the material to the outside, and the outer screw conveys the material to the inside. Under the convection movement of the double helix, the material forms a low dynamic and efficient mixing environment. The inner and outer diameters of the stirring shaft drive the material spirally. Set up ials inside the cylinder, so that the agitator can turn the material inside the cylinder to the maximum. During the operation of the stirring device, the material close to the axis is driven by the screw to rotate axially, and the material close to the cylinder wall is driven externally. The screw rotates axially.

three. Use and maintenance

1 First, start and run without load to see if there are any abnormalities or sounds.

2 Pay attention to whether the motor runs smoothly, without abnormal noise, and whether the temperature rise is normal.

3 After confirming that the no-load startup is normal, add the materials to be mixed according to the production process requirements, close the inlet and outlet valves, and start the spiral belt mixer.

4 Start sequence: according to the process requirements, close the discharge valve-feed-close the lid-start low speed-high speed start-mixing time and temperature feed;

5 Pay attention to check whether the transmission components such as spindle bearings and belts are normal. If there are abnormal sounds and vibrations, stop the rotation immediately, and replace and repair damaged parts in time.

The spiral belt mixer is usually used for the mixing of viscous or agglomerated powder particles, and the mixing of powder particles with liquid and pasty materials. At the same time, because the viscous material is not easy to clean, it is suitable for large-scale production, and various mixing occasions are not frequently changed. In two or three layers, the outer screw converges the material from both sides to the center, and the inner screw convections the material from both sides of the center to form convective mixing.

2. Working principle

The drive shaft of the mixer is provided with double spiral blades. The inner screw conveys the material to the outside, and the outer screw conveys the material to the inside. Under the convection movement of the double helix, the material forms a low dynamic and efficient mixing environment. The inner and outer diameters of the stirring shaft drive the material spirally. Set up ials inside the cylinder, so that the agitator can turn the material inside the cylinder to the maximum. During the operation of the stirring device, the material close to the axis is driven by the screw to rotate axially, and the material close to the cylinder wall is driven externally. The screw rotates axially.

three. Use and maintenance

1 First, start and run without load to see if there are any abnormalities or sounds.

2 Pay attention to whether the motor runs smoothly, without abnormal noise, and whether the temperature rise is normal.

3 After confirming that the no-load startup is normal, add the materials to be mixed according to the production process requirements, close the inlet and outlet valves, and start the spiral belt mixer.

4 Start sequence: according to the process requirements, close the discharge valve-feed-close the lid-start low speed-high speed start-mixing time and temperature feed;

5 Pay attention to check whether the transmission components such as spindle bearings and belts are normal. If there are abnormal sounds and vibrations, stop the rotation immediately, and replace and repair damaged parts in time.

CN

CN

HOME

HOME Kneader shaft wear repair

Kneader shaft wear repair  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address