2.How to maintain the reactor?

May 15,2020

May 15,2020

JCT

JCT

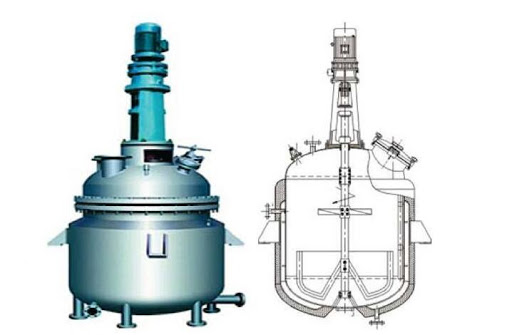

The previous editor has explained the installation and sealing of the kettle body and kettle cover, and the relevant knowledge of the device. Today, the editor continues to bring you the explanation of the installation of valves, pressure gauges and safety valves.

(4) The installation of valves, pressure gauges and safety valves achieves the sealing effect by tightening the positive and negative nuts. The arc sealing surfaces of the two ends must not rotate relative to each other. All screws must be coated with lubricant or Graphite blended with oil to avoid biting. The use of the valve: the needle valve line seals, only need to gently turn the needle, press the cover tightly to achieve good sealing performance, prohibit excessive force, so as not to damage the sealing surface.

(5) After the equipment is installed, pass a certain amount of nitrogen to maintain the pressure for 30 minutes to check for leaks. If you find a leak, please use soap foam to find the leak point of the pipeline and nozzle. After finding out, let go of the gas and tighten it again. Pass nitrogen pressure test to ensure normal operation after no leakage.

(6) When cooling and cooling, water can be used for internal cooling through the cooling coil, and rapid cooling is prohibited to prevent excessive temperature difference stress, causing cracks in the cooling coil and the kettle body. When the temperature in the kettle exceeds 100 ℃ during operation, the water jacket between the magnetic stirrer and the lid of the kettle should be cooled with water to ensure that the water temperature is less than 35 ℃ to avoid demagnetization of the magnetic steel.

Ok, today\'s explanation is here, and I will update your knowledge after installation and cleaning in the kettle later!

CN

CN

HOME

HOME 3.How to maintain the reactor?

3.How to maintain the reactor?  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address