What are the advantages of Horizontal kneader (Sigma mixing mixer)?

Aug 30,2023

Aug 30,2023

JCT

JCT

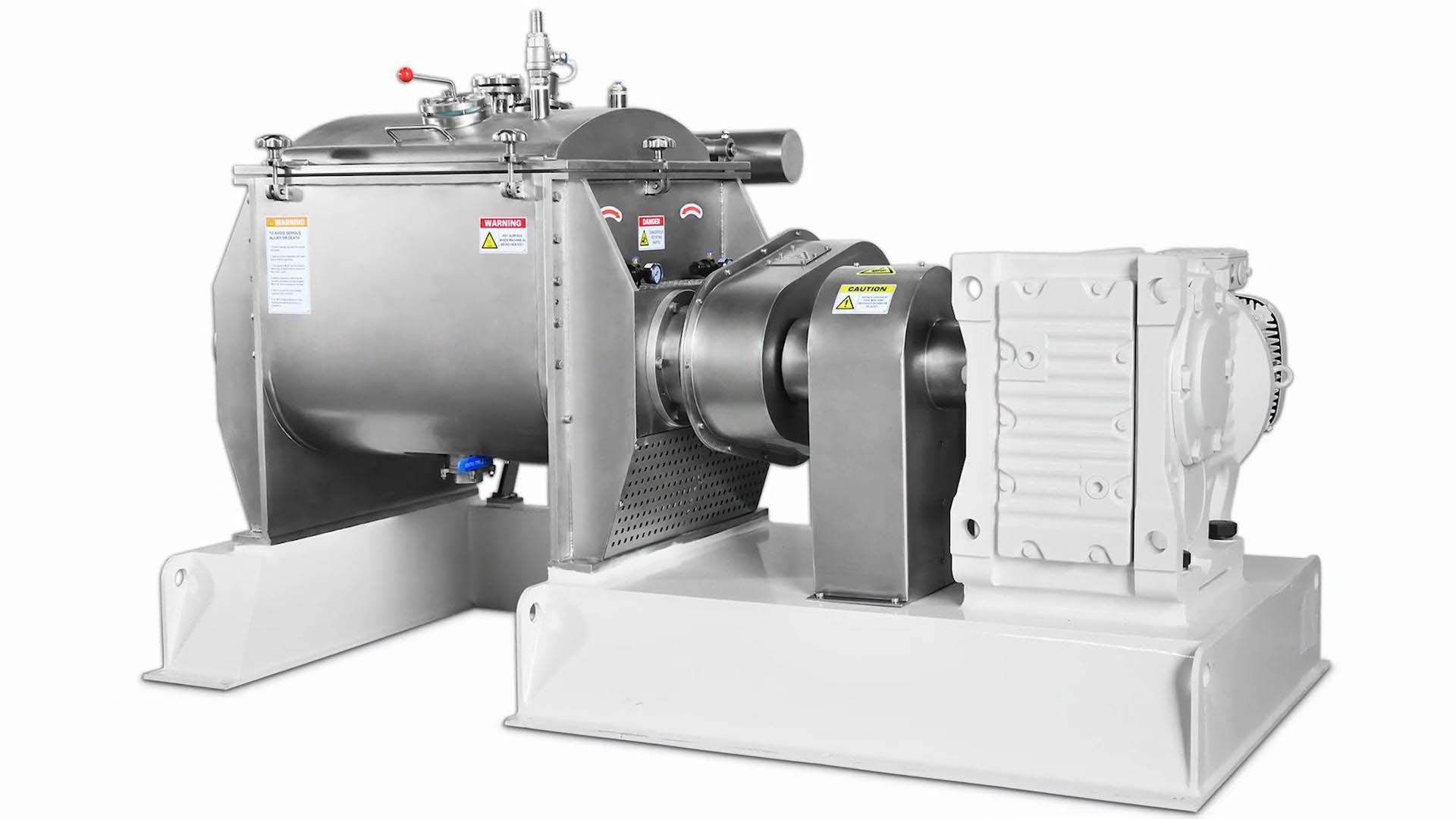

Horizontal kneader,also known as Sigma mixer, is a double-helix mixer, commonly used in industrial equipment for mixing, stirring, homogenizing and processing high-viscosity materials. It has many advantages that make it widely used in various fields. Here are some advantages of Sigma mixers.

1. Suitable for high viscosity materials

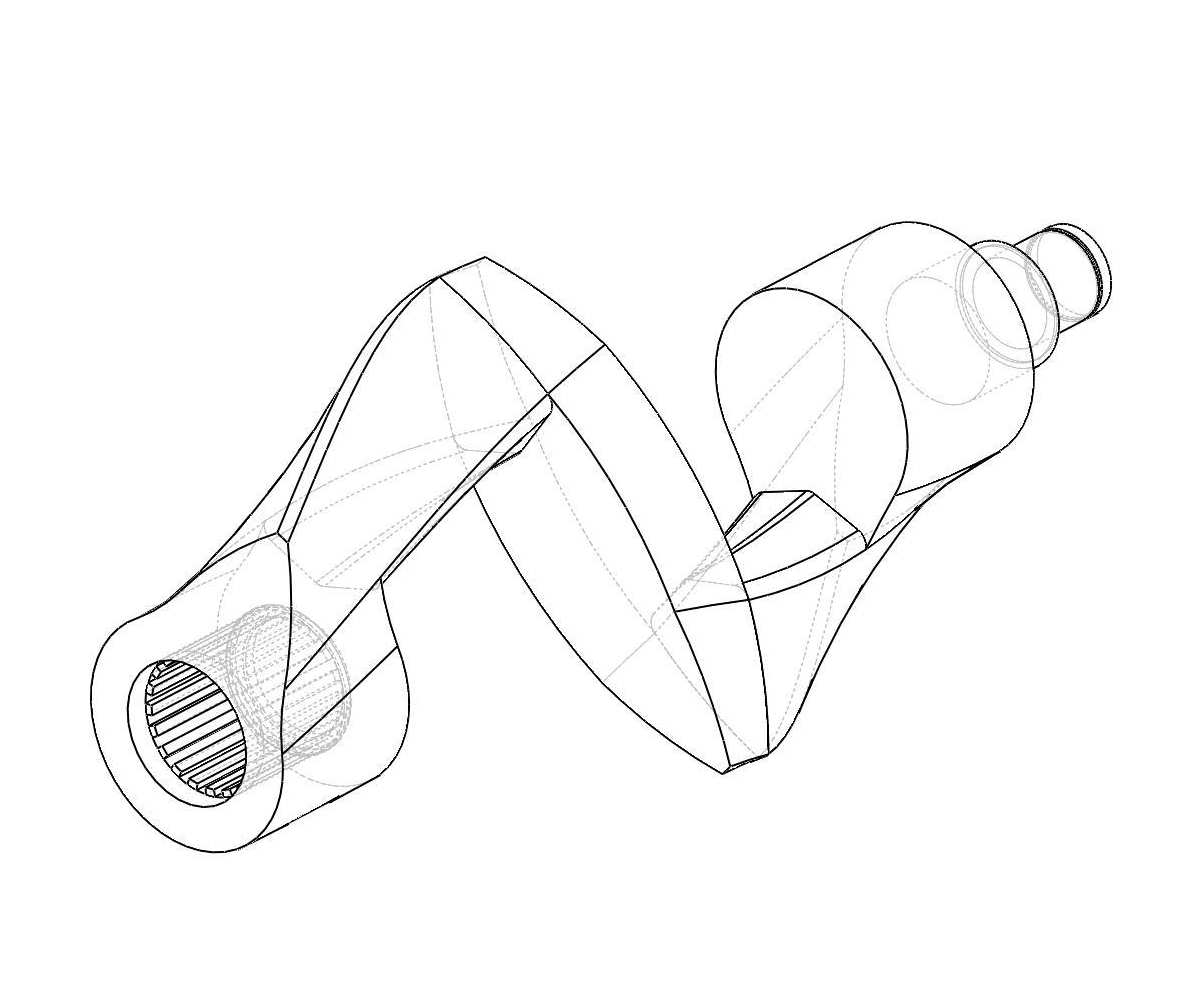

Sigma mixers are ideal for handling highly viscous materials such as glue, glue, asphalt, resins, etc. Its twin helix agitator efficiently mixes and handles these viscous materials, ensuring uniformity and consistency.

2. Intense mixing

The double helix design of the Sigma mixer enables it to provide powerful mixing. This helps to mix the ingredients together thoroughly, ensuring product quality and performance.

3. Uniformity

Sigma mixers are able to maintain material homogeneity throughout the mixing process. This is important for applications where material consistency is required, such as in the pharmaceutical, food and chemical industries.

4. High efficiency

The mixing efficiency of the Sigma mixer is very high. Due to its special agitator design, it can complete the mixing process in a relatively short time, which improves production efficiency.

5. Suitable for multi-component formulations

Sigma mixers can be used to blend multiple materials with different compositions, making them ideal for handling complex recipes. This is useful for making specialty chemicals, pharmaceuticals and food products.

6. Temperature control

Some Sigma mixers are equipped with heating or cooling functions that allow precise control of the temperature of the mixed material. This is important for applications where a specific process requires a specific temperature.

7. High durability

Sigma mixers are generally made of strong materials for high durability. They can run for a long time in harsh working environment and require less maintenance.

8. Security

Most Sigma mixers are equipped with safety features such as guards, safety lockouts and emergency stop buttons to ensure operator safety.

9. Customizability

Sigma mixers can be customized to meet specific production needs. Different sizes, stirrer types, heating/cooling options etc. are available to suit different applications.

10. Wide application fields

Sigma mixers are widely used in chemical, pharmaceutical, food processing, coatings, adhesives, rubber manufacturing, grease and lubricant industries and many other fields.

11. Suitable for mass production

Sigma mixers are generally used in large-scale production and can handle large batches of raw materials to meet the requirements of industrial production.

In a word, Sigma mixer has become the first choice equipment in many industrial fields due to its advantages of being suitable for high-viscosity materials, powerful mixing, high efficiency, uniformity, durability and safety. It plays a key role in chemical, food, pharmaceutical, building materials and other fields, helping to improve production efficiency, product quality and production feasibility.

CN

CN

HOME

HOME What are the differences between hot melt glue sticks and hot melt glue particles?

What are the differences between hot melt glue sticks and hot melt glue particles?  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address