What Is White Carbon Black? | JCT Machinery

Apr 15,2024

Apr 15,2024

JCT

JCT

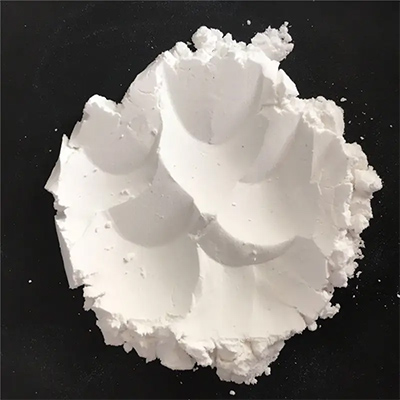

What is white carbon black?

White carbon black is an inorganic compound with the chemical name Silicon Dioxide, also known as Silica White. It is a white, tasteless and odorless powder with a granular or powdery structure, and its main component is SiO₂.

Main Characteristics of White Carbon Black

1. High Specific Surface Area

White carbon black has a very high specidic surface area, usually between 100 and 600 square meters/g, so it has strong adsorption capacity.

2. Fine Particles

The particles of white carbon black are typically very small, typically between 10 and 100 nanometers in diameter, and can therefore have a significant impact on the material's properties at the microscopic scale.

3. Chemical Stability

White carbon black has good chemical stability, acid and alkali resistance, high temperature resistance, and does not easily react with other chemicals.

4. Physical Properties

White carbon black exhibits good dispersion, uniformity and fluidity, and is easy to process and apply.

5. Versatility

White carbon black has strong adsorptioin and filling properties and is commonly used as filler, thickener, whitening agent, adsorbent, etc. It is widely used in rubber, plastics, inks, coatings, medicine, food and other fields.

6. Environmental Protection

White carbon black is non-toxic and harmless, has no harm to the human body and the environment, and is an environmentally friendly material.

The Role of White Carbon Black in Silicone Rubber Production Process

1. Increase the Strength and Hardness of Silicone Rubber

White carbon black is a filler with a high specific surface area that can increase the hardness and strength of silicone rubber. By adding an appropriate amount of white carbon black to silicone rubber, the mechanical properties of silicone rubber can be improved, such as tensile strength, tensile strength and wear resistance.

2. Improve the Heat Resistance of Silicone Rubber

White carbon black has good thermal stability and high temperature resistance, which can improve the heat resistance of silicone rubber. Adding white carbon black to silicone rubber can effectively improve the high temperature stability and aging resistance of silicone rubber.

3. Increase the Wear Resistance of Silicone Rubber

Since white carbon black has excellent wear resistance, adding an appropriate amount of white carbon black can significantly improve the wear resistance of silicone rubber. This is of great significance for silicone rubber products that require long-term wear resistance, such as seals, pipes and conduits.

4. Improve the Processing Performance of Silicone Rubber

An appropriate amount of white carbon black can improve the fluidity and processing performance of silicone rubber, making it easier to process silicone rubber into products of various shapes. In addition, white carbon black can also reduce the shrinkage of silicone rubber and improve the molding accuracy of silicone rubber.

5. Improve Waterproof Performance of Silicone Rubber

White carbon black has good hydrophilicity and can increase the waterproof performance of silicone rubber. In some silicone rubber products that require excellent waterproof performance, such as seals and sealants, adding an appropriate amount of silica can improve the waterproof performance of silicone rubber and reduce moisture penetration.

CN

CN

HOME

HOME Why Choose To Set Up Silicone Rubber Production Line? | JCT Machinery

Why Choose To Set Up Silicone Rubber Production Line? | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address