What Are Characteristics Of Vulcanization? | JCT Machinery

Feb 23,2024

Feb 23,2024

JCT

JCT

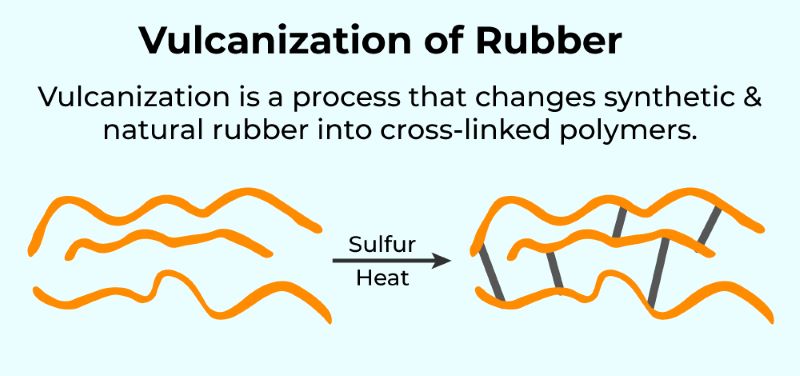

1. Formation of Cross-linked Structure

The main characteristic of vulcanization is the formation of a coss-linked structure. Sulfur atoms combine with some groups in the material to form a three-dimensional network called cross-links. This structure gives the material good elasticity, wear resistance and chemical resistance.

2. Improve Strength and Hardness

Vulcanization often significantly increases the strength and hardness of the material due to the introduction of a cross-linked structure. This is an important advantage for many applications, especially in rubber products.

3. Improve Heat Resistance

Vulcanization usually improves the material's heat resistance. The cross-linked structure can better resist deformation and degradation in high temperature environments.

4. Improve Aging Resistance

The cross-linked structure also helps improve the material's aging resistance, allowing it to maintain stability during long-term use.

5. Reduce solubility

Vulcanized materials generally have lower solubility. This means that vulcanization makes the material more stable in liquids and less likely to dissolve or break down.

6. Improve Electrical Insulation

Some vulcanized materials, especially vulcanized rubber, have good electrical insulation properties and are suitable for some electrical and electronic applications.

7. Adjust Elasticity

By adjusting the vulcanization conditions, the degree of cross-linking can be controlled, thereby adjusting the elasticity of the material. This is an important consideration in the design of rubber products.

8. Resistant to Chemical Corrosion

Because vulcanization introduces a cross-linked structure, vulcanized materials generally have better resistance to corrosion by some chemicals.

CN

CN

HOME

HOME

Vertical Kneader And Planetary Mixer | JCT Machinery

Vertical Kneader And Planetary Mixer | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address