What is the difference between the structure of sigma kneader and banbury mixer?

Jul 05,2017

Jul 05,2017

JCT

JCT

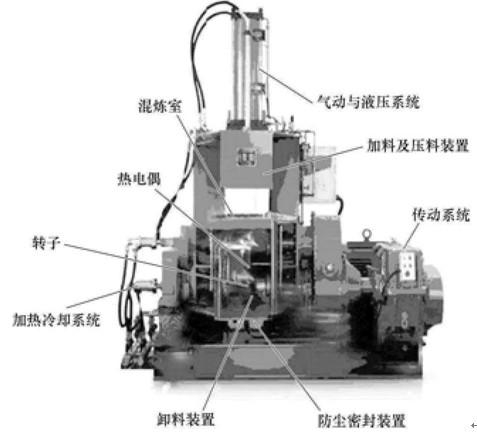

Banbury mixer which is also called close mill, is mainly used for mixing or compounding rubber and plastics. The banbury mixer is a machine in which a pair of specific shapes and relative rotations are provided and the polymer material is masticated and kneaded in a confined state with adjustable temperature and pressure. It is mainly composed of mixing chamber, rotor, rotor sealing device, feeding and pressing device, discharging device, transmission and base. The appearance of the banbury mixer is an important achievement of rubber machinery, and it is still a typical and important equipment for plasticizing and kneading, and is constantly developing and improving.

Sigma kneader is also called open mill, which consists of two different speed Z-shaped blade to produce a strong shear, squeeze, stirring and make material quickly be mixed evenly. The sigma kneader is mainly composed of six parts: kneading part, base part, hydraulic system, transmission system, vacuum system and electric control system. It is widely used in high viscosity sealant, silicone rubber, neutral acid glass glue, chewing gum, bubble gum, pulp, cellulose, ink, pigment, dye, medicine, resin, plastic, rubber, cosmetics and other industries.

As it mentioned above, sigma kneader which also called open mill, that is sigma kneader generally with negative pressure. Banbury mixer has both negative pressure and positive pressure, which means that banbury mixer has a mixing chamber for close mill (with positive pressure), while the sigma kneader did not. As a manufacturer specializing in sigma kneader for many years, we welcome your inquiry!

CN

CN

HOME

HOME

What do you think of artificial marble making prospect?

What do you think of artificial marble making prospect?  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address