Reactor Stirrer Types | JCT Machinery

Jan 17,2024

Jan 17,2024

JCT

JCT

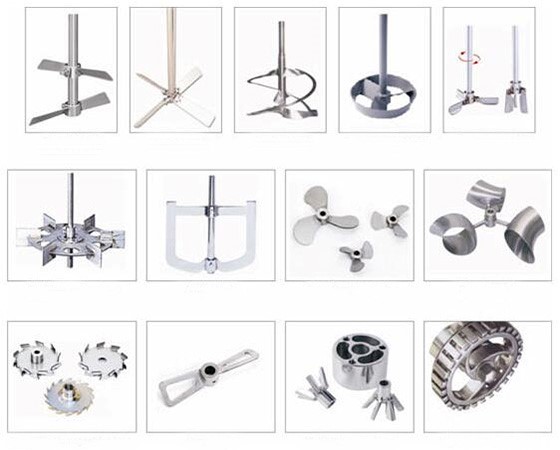

1. Frame stirrer

Frame stirrer is one of the most common stirrer types in reactors. It consists of one or more straight frames connected in series on axes perpendicular to the bottom. Frame stirrer is suitable for mixing low-viscosity liquids and gases. It has a simple structure and is easy to maintain, but it cannot stir materials that are too viscous.

2. Paddle stirrer

Paddle stirrer is suitable for mixing materials with higher viscosity, such as pastes and typical fluidized particle beds. It usually consists of one or more flat paddles mounted on the mixer shaft, which can provide a more uniform mixing effect than frame stirrer.

3. Propeller stirrer

Propeller stirrer is suitable for mixing high viscosity liquids such as coatings and paints. It consists of one or more blades with a spiral cross section and a shaft perpendicular to the bottom. The propeller agitator provides high-intensity mixing and is easy to install and disassemble.

4. Anchor stirrer

Anchor stirrer is suitable for mixing high-viscosity materials such as colloids and slurries. It consists of one or more anchor-shaped blades and a shaft perpendicular to the base. Anchor agitators provide very uniform mixing results, but due to the gap between the blades and the container wall, there may be dead spots for materials with higher handling requirements.

5. Turbine stirrer

Turbine agitator is suitable for stirring high-speed gas flows and liquid mixtures. Depending on the use environment, they can be of a top-plug structure. The top-mounted structure is installed on the top and generates linear motion, which can procide very strong shear and disturbance effects. The drop-down structure can provide lower shear and reduce gas consumption.

CN

CN

HOME

HOME

What Is PVA Glue Characteristic? | JCT Machinery

What Is PVA Glue Characteristic? | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address