Reactor For Resin Production | JCT Machinery

Mar 24,2025

Mar 24,2025

JCT

JCT

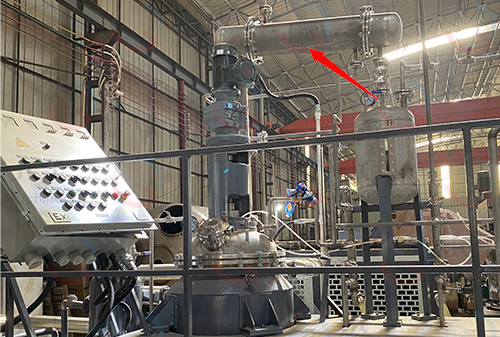

1. Control temperature to achieve precise reaction

Resin production is usually an exothermic or endothermic reaction, such as unsaturated polyester resin, epoxy resin, phenolic resin, etc., which requires strict temperature control.

Reactor is equipped with a jacket or coil, which can be heated by steam, thermal oil or water to ensure that the reaction is carried out within the optimal temperature range to prevent side reactions or degradation.

2. Strong stirring to promote uniform mixing

Resin production involves monomer polymerization, polycondensation reaction, and cross-linking reaction. It is necessary to ensure uniform mixing of materials to avoid local overheating or uneven components.

Reactor is usually equipped with different types of stirring devices (anchor type, paddle type, frame type, dispersion disc, spiral ribbon type, etc.). Choose the appropriate stirring form according to the viscosity and rheological properties of the resin to ensure efficient mixing.

3. Applicable to a variety of chemical reactions

- Unsaturated polyester resin requires high temperature esterification reaction.

- Epoxy resin requires controlled cross-linking polymerization reaction.

- Phenoloc resin requires acid-base catalyzed condensation reaction.

4. Vacuum degassing, reducing bubbles and improving resin quality

During the production process, bubbles will affect the transparency, mechanical properties and fluidity of the resin, especially high-end resins such as electronic packaging resins and optical grade resins.

Reactor can be equipped with a vacuum system to evacuate at the appropriate stage to effectively remove solvents, low molecular byproducts or bubbles, and improve resin product purity and quality.

5. With solvent recovery function, energy saving and environmental protection

Some resin production processes use solvents (such as acetone, toluene, styrene, etc.), which need to be recycled.

Reactor can be equipped with a condenser and a recovery tank to efficiently recover solvents, reduce waste, and meet environmental protection requirements.

6. Easy to automate and improve production efficiency

Resin production has high requirements for stability, consistency and controllability. The reactor can be integrated with a PLC control system to achieve:

- Automatic monitoring of temperature, pressure and stirring speed

- Precise feeding, automatic heating/cooling

- Data recording, intelligent management

Through automated control, manual intervention can be reduced, production efficiency can be improved, and operational errors can be reduced.

CN

CN

HOME

HOME Dental Resin Material Vertical Kneader | JCT Machinery

Dental Resin Material Vertical Kneader | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address