Process flow chart of mask production line equipment

Mar 19,2020

Mar 19,2020

JCT

JCT

Process flow chart of mask production line equipment

Since the outbreak of the new crown pneumonia virus, "a mask is hard to find" has become a hot topic instantly. How can a small mask block the terrible virus? Now, I will first review the mask production equipment and production process with you!

equipment:

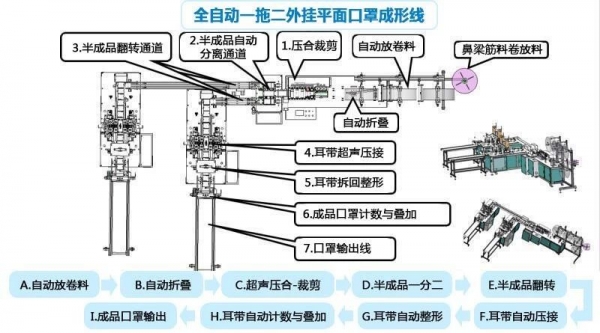

Full-automatic flat mask machine is a one-to-two production line, consisting of a mask body machine and two ear band machines

effectiveness:

one for two machine:80-110pcs/min.

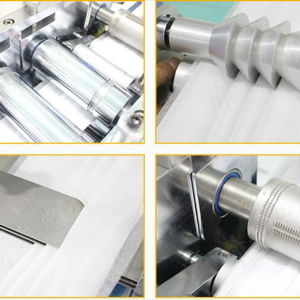

Mask body machine

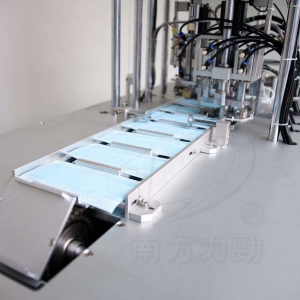

Mask ear strap machine

Operating procedures:

After the entire roll of fabric is unrolled, it is driven by rollers, and the fabric is automatically folded and hemmed. The nose roll is rolled and unwound. It is cut into lengths and then introduced into the hemmed fabric. The two sides are ultrasonically welded to the seal and then ultrasonically sideways Sealing, cutting and shaping with a cutter; conveying the mask to the two mask earband welding stations through the assembly line, and finally forming the mask by ultrasonic welding; when the mask is made, it is conveyed to the flat belt line for collection through the assembly line.

FLOW CHART

Today, I will introduce mask equipment and process flow to you first. JCT Machinery Equipment Co., Ltd. where the editor is located is a professional manufacturer of mask equipment. If you want to learn more about hand sanitizer production line equipment, you can contact Xiao Editor:

website : www.nhjct.cn

telephone:+86-0757- 8625 3526;

Email:[email protected]

Mobile: 0086-13929992673(WhatsApp)

18028192316

If you need to know the detailed equipment configuration, production technology, production process, please contact us.

CN

CN

HOME

HOME What equipment do I need to make a hand sanitizer?

What equipment do I need to make a hand sanitizer?  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address