How is lubricant grease manufacturing process?

Jul 03,2017

Jul 03,2017

JCT

JCT

With the continuous development of the machinery industry, the demand for grease increases. Grease is a thick grease-like semi-solid, it is mainly used for friction part of the mechanical movement, with the lubrication and sealing effect. And it is also used for metal surface, with effects of filling the gap and anti-rust. How is lubricant grease manufacturing process? And what equipments does it need? Now let me talk about the production process for grease for you.

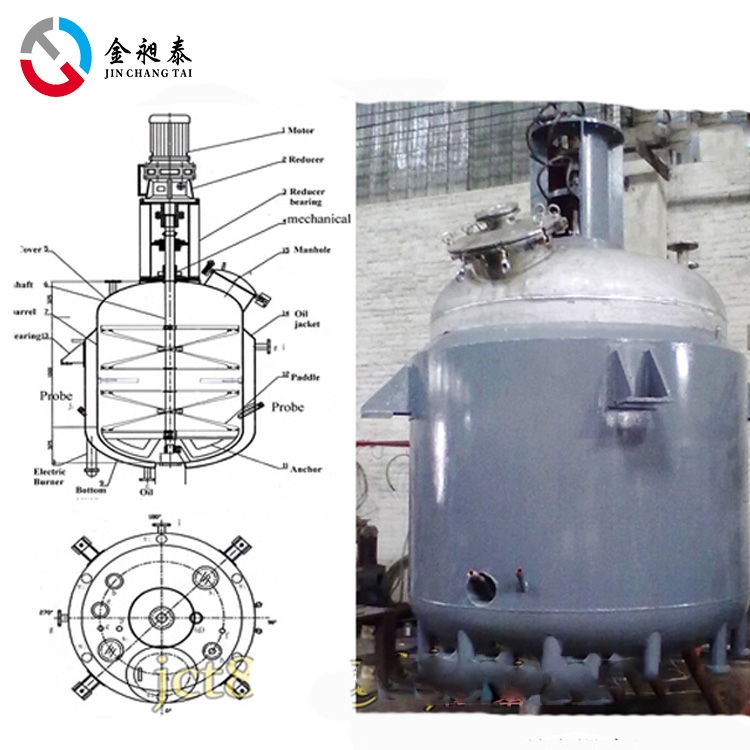

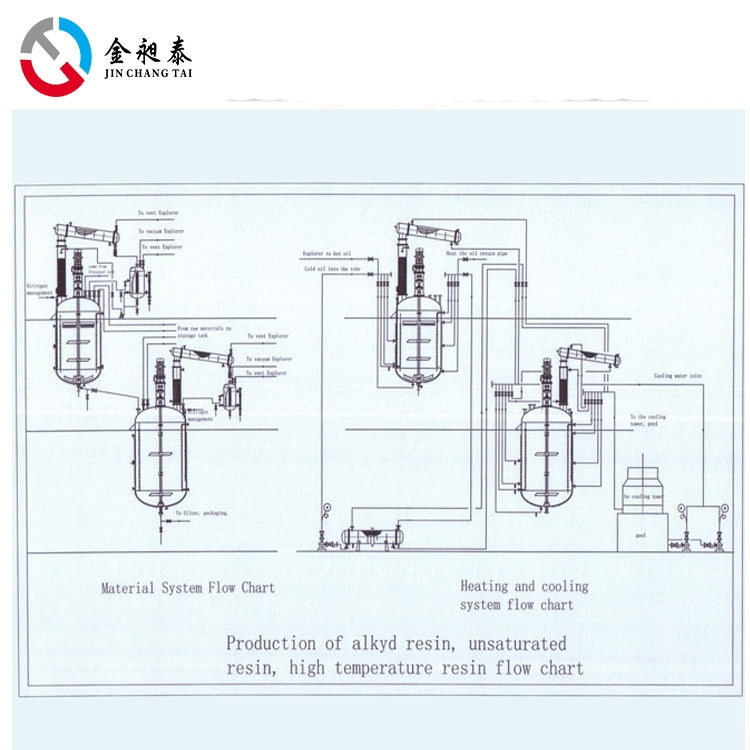

For the main equipments for lubricant grease manufacturing process, there are two main options: reactor and dual powerful planetary mixer. As the choice of equipment is not the same, the quality of the product be produced is not the same, either. The latter\'s product quality will be higher than the former. But the cost will be much higher, so if the product quality is not too strict, then using the reactor will be ok. Let me take you to understand lubricant grease manufacturing process which uses reactor.

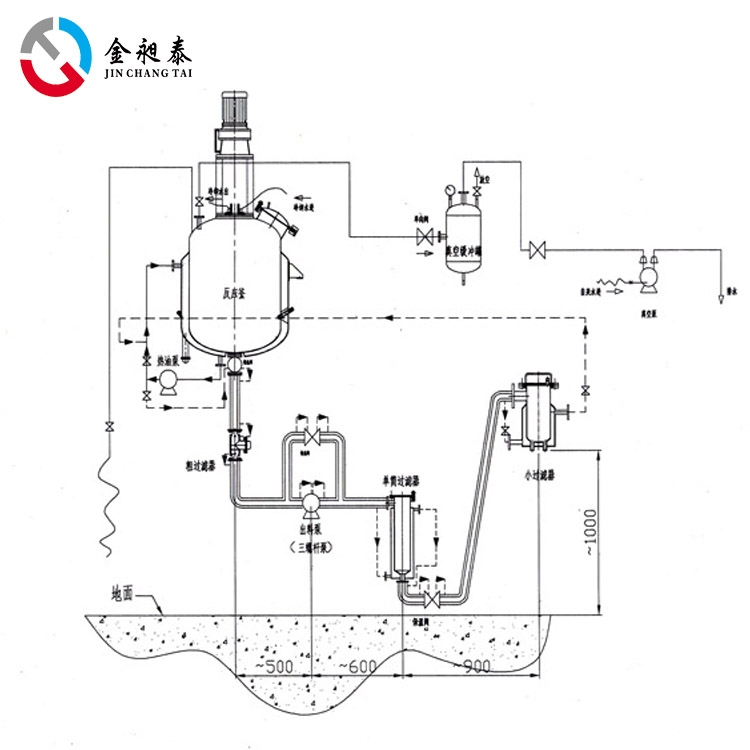

When using reactor for main equipments, lubricant grease manufacturing process is as follows: Mixing equipment (Using reactor to agitate, you can add a kettle or tank to improve efficiency) - Vacuum devices (including vacuum pumps, vacuum buffers and link pipes) - Cooling device (condenser) - heating device (electric heating or oil furnace heating, oil pump) - feeding device (trough, feeding pump) - discharge device (discharge ball valve, discharge pump, filter, discharge valve ) - Filling equipment (automatic / semi-automatic). If you are interested in know more about lubricant grease manufacturing process to start your grease making project, you can contact with JCT Machinery!

CN

CN

HOME

HOME

Client who from Bangladesh come to visit JCT Machinery's colour pigment manufacturing machines

Client who from Bangladesh come to visit JCT Machinery's colour pigment manufacturing machines  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address