Industrial Paint Mixer | JCT Machinery

Jun 19,2024

Jun 19,2024

JCT

JCT

JCT Machinery Paint Production Line Turnkey Project Equipment Configuration

- High speed disperser

- Horizontal sand mixll

- Vacuum system

- Paintt mixing kettle

- Fast open bag filter

- Paints filling machine

- The specific configuration is based on the actual needs.

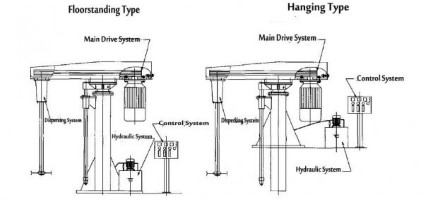

High speed disperser is a common industrial paint mixer.

Main Components of Industrial Paint Mixer

1. Dispersing Disc

Usually made of stainless steel or other wear-resistant materials, there are many forms such as toothed disc or impeller, choose the appropriate type according to your needs.

2. Shaft

Connects the dispersing disc and the frive motor to transmit rotatioinal power.

3. Drive Motor

Provides a power source for high speed rotation, usually a variable frequency motor, which can adjust the speed.

4. Lifting System

The mixing head can be moved up and down by hydraulic or electric lifting devices, which is convenient for operation and cleaning.

5. Control System

The speed, lifting and running time of tthe disperser are controlled by PLC or frequency converter.

6. Mixing Vessel

The container for holding the materials to be mixed, usually equipped with a jacket, which can heat or cool the materials.

Advantages of Industrial Paint Mixer

1. Efficient Dispersion

High speed rotation generates strong shear force, which quickly disperses solid particles, shortens mixing time and increases efficiency.

2. Easy Operation

Industrial paint mixer has a simple structure, is easy to operate, and is easy to clean and maintain.

3. Wide Application Range

It can handle a variety of materials with different viscosities, and can efficiently disperse liquids from low viscosity to high viscosity.

4. Automated Control

Equipped with an automated control system, it can accurately control the dispersiion time and speed improving production consistency and quality.

CN

CN

HOME

HOME About EVA Hot Melt Gue | JCT Machinery

About EVA Hot Melt Gue | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address