Do you know how to deal with these conditions when the industrial fermenter mixing reactor is in use?

Jul 22,2017

Jul 22,2017

JCT

JCT

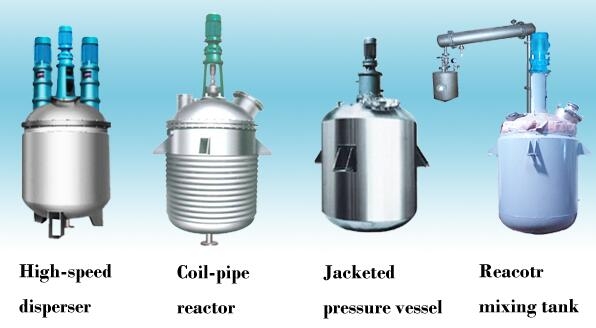

In the daily use of the industrial fermenter mixing reactor, with the passage of time, sometimes there will inevitably be some minor problems, but sometimes if we directly contact the manufacturers to come to deal with, often found that these problems are very simple can be resolved.

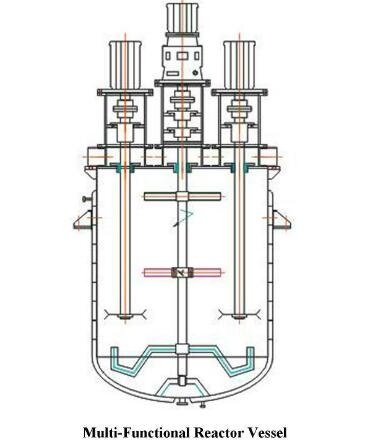

First, the industrial fermenter mixing reactor suddenly appeared noiseIn general, the reactor has a noise, most of the reason is stirrer friction inside the kettle, such as the snake tube, thermometer tube or wall stirrer loose, lining drum and stirrer impact, stirrer bending or bearing damage.

Common solutions are:

1. Reactor shutdown maintenance, correction, so that the mixer and accessories have a certain spacing.

2. Stop running, check, fasten the bolts.

3. Repair the part or replace it.

4. Repair, or replace the mixing bracket bearings of the reactor

In general, there are some possible reasons that the motor current of the reactor exceeds the rate or set value: bearing damage, low temperature inside the reactor, material\'s high viscosity, spindle speed faster, agitator diameter is too large and so on.

Solution:

1. Replace the reactor with the stent bearing

2. According to the reactor operating procedures to adjust the temperature, material viscosity can not be too high

3. Control the spindle speed in a certain range

4. Adjust the diameter and angle of the mixing blade

1. Generally because the reactor work instrument produces over-temperature, overpressure phenomenon, instrument failure, control is not strict.

Solution: check, repair control device, strictly enforce the operating procedures, while stopping other operations.

2. Improper operation such as improper proportion of raw materials; produce a severe reaction.

Solution: According to the operating method, take emergency pressure relief, in strict accordance with the operating procedures.

3. due to heat transfer or agitator performance is poor, resulting in side effects.

Solution: According to the actual experience to adjust, under normal circumstances, such as the thermometer shows running a temperature difference within a certain range. If the deviation is large, check the probe or conveyor. Increase the power of the stirrer, and provide the heat transfer effect of heating.

4. Reactor intake valve aging or intake pressure is too large.

Solution: close the total intake valve, maintenance.

More problems about maintenance of industrial fermenter mixing reactor you have can feel free to contact us!

CN

CN

HOME

HOME

Saudi Arabian client visited JCT Machinery for discussing best super glue production line equipment

Saudi Arabian client visited JCT Machinery for discussing best super glue production line equipment  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address