Do you know high temperature silicone rubber manufacturing process?

Aug 01,2017

Aug 01,2017

JCT

JCT

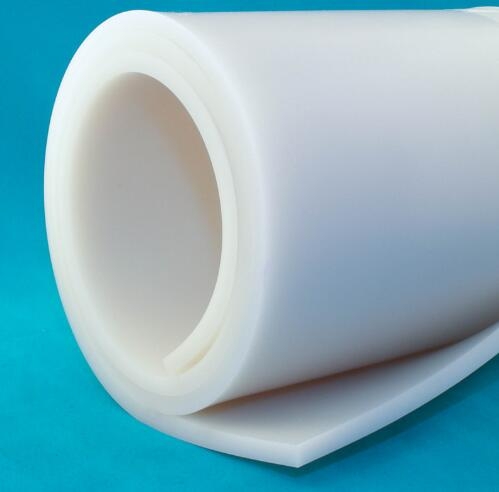

Speaking of silicone, we are more or less have heard, but today i would like to tell you something about silicone rubber. It is generally used in aviation, electronic appliances, automobiles, medical, construction and so on. As the application is very wide, the market is also very broad. So now more and more people start engage in this industry field. Do you know high temperature silicone rubber manufacturing process?

1. Preparation of raw materials according to the formula, adding Vinyl silicone rubber, silicone oil, release agent to the kneader, Stirring. Powder raw materials are added for many times.

2. To increase the temperature of the material, it need to be stirred continuously. When the temperature reaches the required temperature of the process, the ice water cooling temperature control.

3. Pour the mixture into receiving trolley.

4. The material is cooled down by an open two-roller mill. Transfuse ice water into the open two-roller mill.

5. The high temperature silicone rubber is filtered and molded, Then cutting it and packing it.

This is the basic process of high temperature silicone rubber, if you want to learn more detailed high temperature silicone rubber manufacturing process, or equipment configuration, you can directly contact JCT Machinery.

CN

CN

HOME

HOME

What do you know about PU glue( polyurethane adhesive)?

What do you know about PU glue( polyurethane adhesive)?  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address