High Speed Disperser Blade | JCT Machinery

Sep 02,2024

Sep 02,2024

JCT

JCT

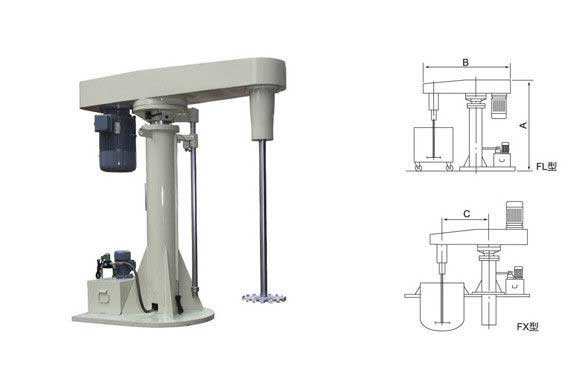

High Speed Disperser Working Principle

High Speed Disperser Working Principle

Working principle of high speed disperser is to disperse the sample through the high-speed movement of the rotor and impeller to achieve uniform dispersion or emulsification. Under high speed movement, the dispersing disc will produce a large shear force and impact, causing the molecules inside the sample to change, thereby achieving mutual dissolution, mixing or dispersion.

Common Types of Dispersing Discs For High Speed Disperser

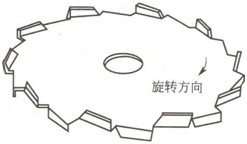

1. Flat Disc Serrated Dispersing Disc

The serrated design is suitable for occasions with high shear force requirements and is widely used for high speed dispersion of materials such as pigments, paints and coatings.

2. Double-layer Serrated Dispersing Disc

It is composed of two layers of serrated discs, which enhances the dispersion effect and is suitable for materials with higher viscosity.

3. Spiral Dispersing Disc

The disc is designed with spiral blades, which can enhance the up and down circulation effect of the material and is suitable for materials with medium viscosity.

4. Turbine Dispersing Disc

The disc has arc-shaped or right-angle blades, which is suitable for the dispersion of low-viscosity and high-fluidity liquids.

5. Hole Dispersing Disc

There are multiple small holes on the disc for rapid dispersion and mixing of materials, which is suitable for materials with low to medium viscosity.

6. Three-leaf Dispersing Disc

It is suitable for materials that require greater fluidity and medium shear force, effectively improving the mixing efficiency.

CN

CN

HOME

HOME About Polyvinyl Alcohol | PVA | JCT Machinery

About Polyvinyl Alcohol | PVA | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address