Gunpowder Simga Mixer | JCT Machinery

Jan 09,2026

Jan 09,2026

JCT

JCT

1. Superior Mixing Uniqueness and Kneading Capability

Unique blade design: Its two ∑-shaped blades rotate in opposite directions with a speed difference, generating strong shearing, folding, stretching, and extrusion forces on high-viscosity, paste-like, or greasy materials (such as wet propellant or propellant slurry). This "kneading" process is crucial for ensuring the microscopic uniform distrubution of oxidizers, fuels, binders, and other additives, directly determining the consistency of propellant performance.

No dead-angle mixing: The blade shape precisely matches the cylinder wall, effectively scraping the cylinder walls and bottom, ensuring all materials participate in circulating mixing and avoiding localized unevenness or sedimentation.

2. High Safety and Controllable Process

Seamless design: Sigma mixer can be designed as a fully sealed enclosure, allowing operation under inert gas protection (such as nitrogen) or in a vacuum environment.

- Explosion-proof and oxidation-proof: Isolates from air, preventing flammable materials from contacting oxygen and venting any potentially accumulated volatile gases, greatly reducing the risk of combustion and explosion.

- Air bubble removal: Air bubbles in the slurry can be removed under vacuum conditions. Air bubbles can cause defects during subsequent curing or stretching processes, affecting product quality and safety.

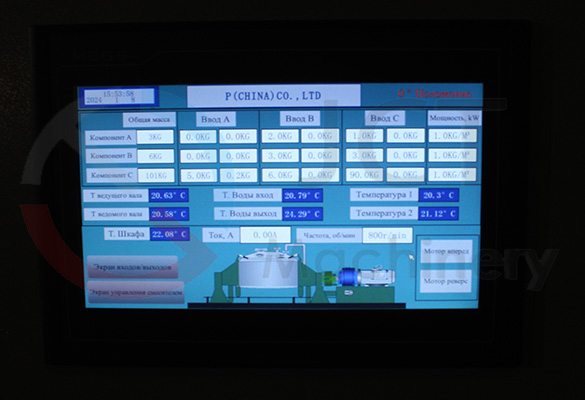

Mild temperature control system: Sigma mixer is typically jacketed, allowing for the flow of cooling water or heating medium to precisely control the process temperature. For exothermic or heat-sensitive processes such as gunpowder mixing, preventing localized overheating is crucial for safety.

Anti-friction spark design: Key components may utilize special alloys or designs to prevent sparks generated by metal-to-metal friction.

3. Suitable For High-viscosity, High-solids-content Materials

Modern composite propellants and propellants are often viscous pastes containing a large number of solid particles. The powerful torque and mechanical structure of sigma mixer are designed to handle these high-viscosity, high-shear-resistance materials, which is beyond the capabilities of ordinary mixers.

Sigma Mixer's "Theoretical Fit":

- Low speed, high torque (reduced impact)

- Material is tumbled as a whole, rather than scattered at high speed

- Seamless structure

- Remote/isolated operation design

The gunpowder sigma mixers we provide have been verified by our customers in production and are safe and reliable.

If you are also interested in gunpowder sigma mixer, feel free to contact us: +86-18138373963 (Whatsapp, Wechat) or [email protected].

CN

CN

HOME

HOME Continuous Accumlation Of Chemical Equipment And Production Line Solutions | JCT Machinery

Continuous Accumlation Of Chemical Equipment And Production Line Solutions | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address