Design of Ribbon Mixer | JCT Machinery

Jan 19,2024

Jan 19,2024

JCT

JCT

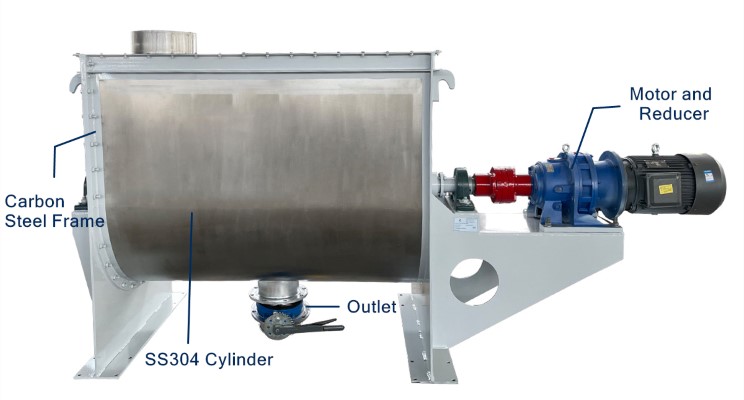

The disgn of ribbon mixer involves various factors to ensure efficient and homogeneous mixing of dry powders, granules, or other solid materials. Here are key aspects considered in the design of ribbon mixer:

1. Double Helical Ribbon Blades: Ribbon mixer typically features two helical ribbon blades that are mounted on a central shaft. The helical design enhances the mixing action as the ribbons move materials both radially and laterally within the mixing chamber.

2. Mixing Chamber (Trough)

(1) U-shaped Trough: The trough or mixing chamber usually has a U-shaped design to facilitate material movement and prevent dead zones.

(2) Jacketed Trough: Some ribbon mixiers may have a jacketed trough for temperature control, allowing heating or cooling of the materials during mixing.

3. Material of Construction: The construction material is selected based on the application and the nature of the materials being processed. Stainless steel iis often used for applications requiring corrosion resistance, while carbon steel is suitable for many industrial applications.

4. Ribbon Design

(1) Ribbon Width and Thickness: The width and thickness of the ribbons influence the intensity of the mixing. These dimensions are chosen based on the specific requirements of the materials being processed.

(2) Clearance from Trough Walls: Adequate clearance between the ribbon blades and the trough walls is maintained to prevent material buildup and ensure efficient mixing.

5. Drive System

(1) Motor Power and Speed: The motor power and speed are selected to meet the mixing requirements. Variable speed drives may be incorporated for flexibility.

(2) Gearbox: A gearbox is often used to transmit power from the motor to the mixing shaft.

6. Discharge Mechanism

(1) Discharge Gate or Valve: Ribbon mixer typically has a discharge gate or valve at the bottom of the trough for controlled discharge of the mixed materials.

(2) Tilt Mechanism: Some ribbon mixers may include a tilting mechanism to assist in discharging materials.

7. Safety Features

(1) Lid with Safety Interlocks: Ribbon mixer may has a safety lid with interlocks to prevent access during operation.

(2) Emergency Stop Button: An emergency stop button provides a quick means to halt the mixer in case of emergencies.

8. Temperature and Speed Controls: Advanced ribbon mixers may include controls for adjusting mixing temperature and rotational speed.

CN

CN

HOME

HOME Get To Know Polyester Unsaturated Resin | JCT Machinery

Get To Know Polyester Unsaturated Resin | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address