What is the structure and principle of stainless steel reactor?

Aug 25,2022

Aug 25,2022

JCT

JCT

一. The shell of the reactor

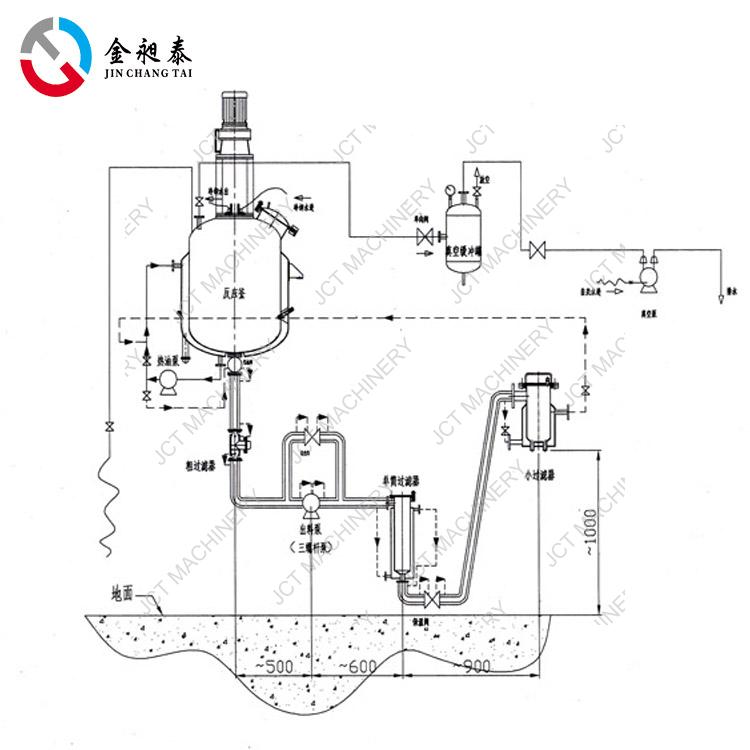

The shell provides the effective volume of the reactor to ensure the completion of production tasks, and has sufficient strength and corrosion resistance to ensure reliable operation. The utility model is composed of a cylinder, an upper cover and a lower seal. There are two ways to connect the cover to the cylinder. One is to directly weld the cover and the cylinder into a whole; the other is to consider disassembly and facilitate flange connection. The upper cover is provided with manholes, hand holes and process connection holes.

二. Stirrer of the reactor

The stirrer is a key component of the stainless steel reactor. Whether the selection and calculation of the agitator is correct is directly related to the operation and reaction results of the agitated reactor. If the agitator cannot mix the materials uniformly, it may cause some side reactions, deterioration of product quality, reduction of yield, and serious deviation of reaction results from small-scale test results, the so-called amplification effect.

三. The sealing device of the reactor

The sealing device used in the reaction equipment is a dynamic sealing structure, mainly including packing seals and mechanical seals. The reactor stirrer is the main component to realize the mixing operation. Its main component is the impeller. It imparts mechanical energy to the liquid through the movement of the rotating shaft and facilitates the movement of the liquid. Mix materials evenly, strengthen heat and mass transfer, including uniform liquid mixing; liquid-liquid dispersion; gas-liquid dispersion; solid-liquid dispersion; crystalline solid dissolution; enhanced heat transfer, etc.

四、Features of stainless steel reactor:

1.Overall material: 304/316L standard material, other metal materials can be selected.

2.Stirring method: Jack-up mechanical stirring with adjustable speed. Sealing technology: anti-corrosion and pressure-resistant materials, pressure range: 0.5-1.6mpa, which solves the problems of sealing leakage of traditional reactors and the inability of glass reactors to withstand pressure.

3.Kettle body structure: jacket design, the jacket can be filled with heat-conducting oil, water and other solvents.

4.Stirring motor: high-power motor, high power, fast speed and good stability.

5.Speed control structure: high-speed digital display, high sensitivity.

6.Inlet valve: built-in extension tube, which can be filled with hydrogen.

7.Exhaust valve: large diameter exhaust design.

8.Pressure gauge: stainless steel 316L, shockproof, corrosion-resistant, durable, real-time monitoring reaction pressure.

Jin Chang Tai Chemical Machinery Co., Ltd.

welcome to our website: /

Phone:+86-13929992673 whatapp:13929992673

Mailbox:[email protected]

Thank you very much !

CN

CN

HOME

HOME How long is the life of the jacketed reactor?

How long is the life of the jacketed reactor?  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address