Horizontal ribbon mixer can produce the putty powder

Jan 12,2018

Jan 12,2018

JCT

JCT

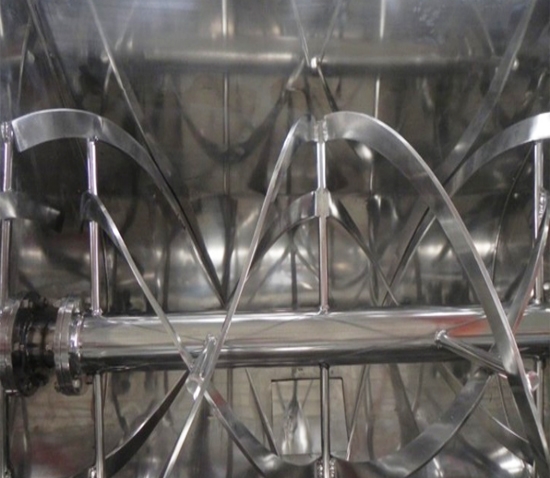

Horizontal ribbon mixer is arranged on the drive spindle double helical blades, the internal spiral material to the outside delivery, the external spiral to the material gathered to the interior. Material in the double spiral belt convection movement, the formation of a low-power high-efficiency mixed ring environment. In addition, the inner and outer diameter screws installed on the stirring shaft drive the material in the barrel so that the agitator can flip the material in the widest range of the barrel.

Horizontal ribbon blender mixing device work, the inner helix drive shaft near the center axis of rotation, the axial from the inside to both sides of the push, driven by the outer wall of the barrel material near the axis of rotation. The axial from the two Push the side to the bottom, mixer out of the bottom of the way, the powder material pneumatic open the door structure. In the need to heat or cooling occasions, can be configured jacket, electric heating and heat conduction oil heating two ways.

The horizontal ribbon motor is directly connected with the main shaft through the cycloid reducer with simple structure, high operation reliability and easy maintenance. Horizontal ribbon mixer is widely used in solid-solid (ie powder and powder), solid-paste (ie, putty paste, real stone paint, dry powder, putty powder, medicine, foodstuffs, chemicals, feed, ceramics, refractory materials, Powder and glue solution), especially suitable for mixing thick materials.

CN

CN

HOME

HOME

The hot melt glue production line supplier

The hot melt glue production line supplier  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address