A good reactor determines the quality of hot melt glue sticks?

Oct 27,2021

Oct 27,2021

JCT

JCT

The hot melt glue stick is white and opaque (strong type), non-toxic, easy to operate, and there is no carbonization in continuous use. It has the characteristics of fast bonding, high strength, aging resistance, non-toxicity, good thermal stability, and film toughness.

Advantages of hot melt glue stick:

1. The hot melt glue stick has fast bonding speed, convenient for continuity, automatic high-speed work, and low cost.

2. No solvent pollution and no burning.

3. No drying process is required, and the bonding process is simple.

4. The product itself is solid, which is convenient for packaging, transportation and storage, with a small footprint and convenient storage.

5. It has good bonding strength and flexibility.

6. A wide range of bonding objects, that is, bonding and sealing.

7. Good gloss and gloss retention, good shielding performance.

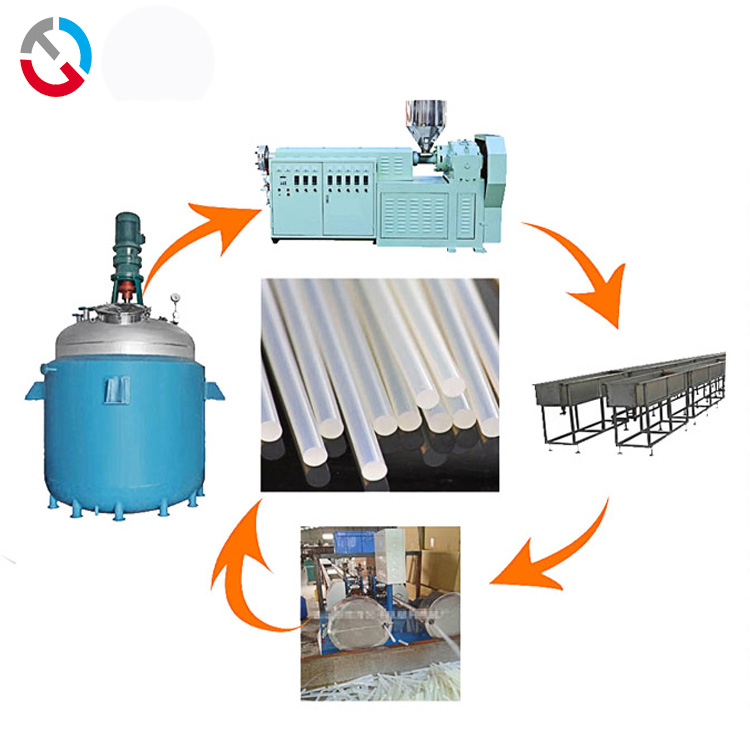

The main production machine of hot melt glue stick is reactor.JCT Machinery has specialized in Reactor manufacturing since 2006.

The reactor is composed of a kettle body, a kettle cover, a jacket, a stirrer, a transmission device, a shaft sealing device, and a support. The stirring form generally has anchor type, paddle type, turbine type, propeller type or frame type, etc. When the height of the stirring device is relatively large, multi-layer stirring blades can be used, or it can be arbitrarily selected according to user requirements. A jacket is arranged outside the wall of the kettle, or a heat exchange surface is arranged in the vessel, and heat exchange can also be carried out through an external circulation. Heating methods include electric heating, hot water heating, heat-conducting oil circulation heating, far infrared heating, outer (inner) coil heating, etc. The cooling methods are jacket cooling, kettle inner coil cooling, and stirring blades. The supporting seat has a supporting type or an ear type supporting seat and so on. A gear reducer should be used if the speed exceeds 160 rpm. The number of holes, specifications or other requirements can be designed and manufactured according to user requirements.

We can customize reactor and professional guidance according to your requirements.If you would like to know more information about the equipment,You can contact me : Phone:+86-13929992673 whatapp:13929992673 , Mailbox:[email protected], I will answer for you in detail.

CN

CN

HOME

HOME

Power mixer capable of making paste cosmetics

Power mixer capable of making paste cosmetics  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address